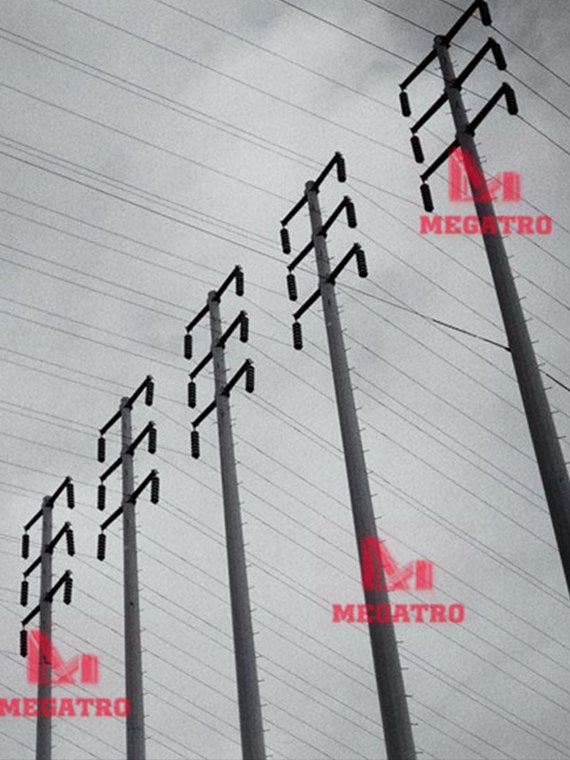

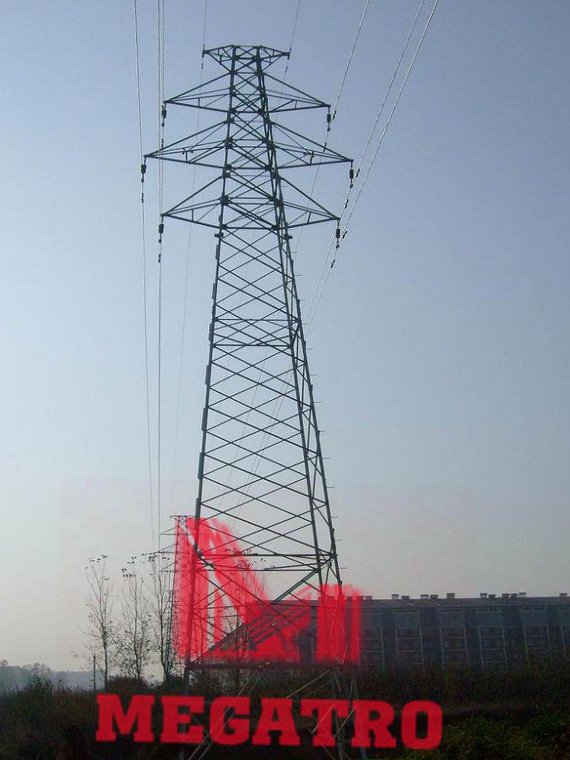

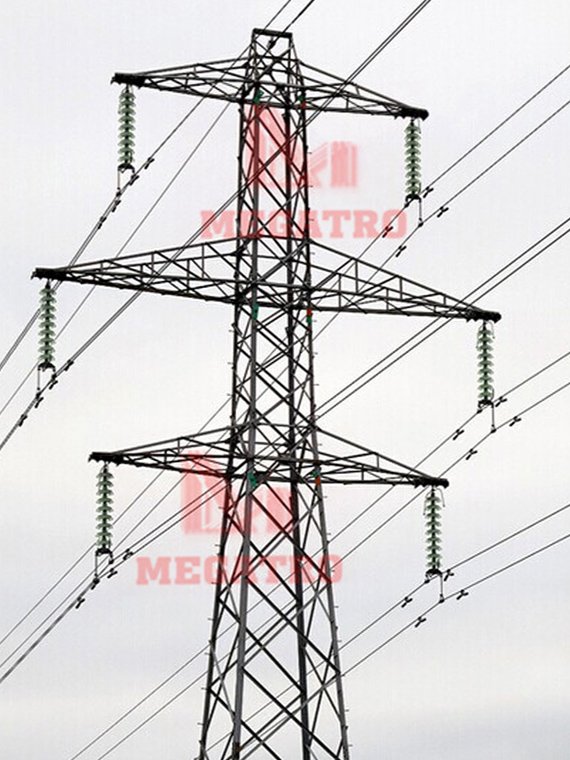

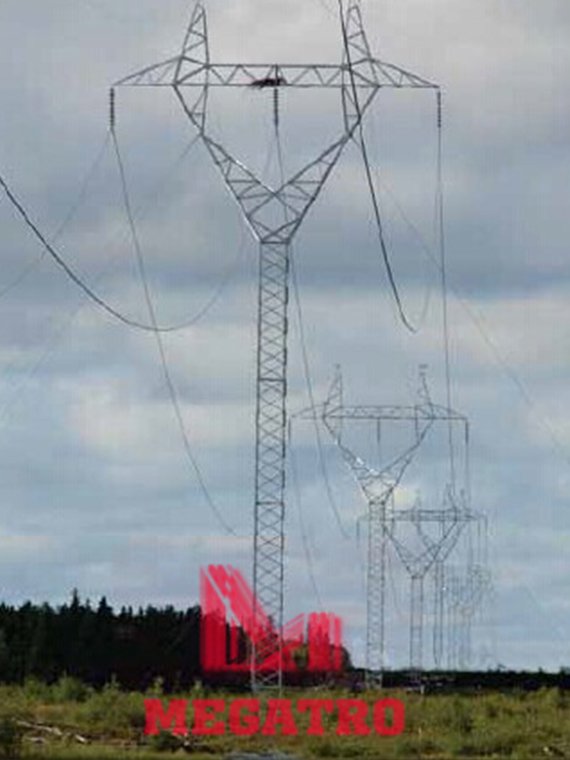

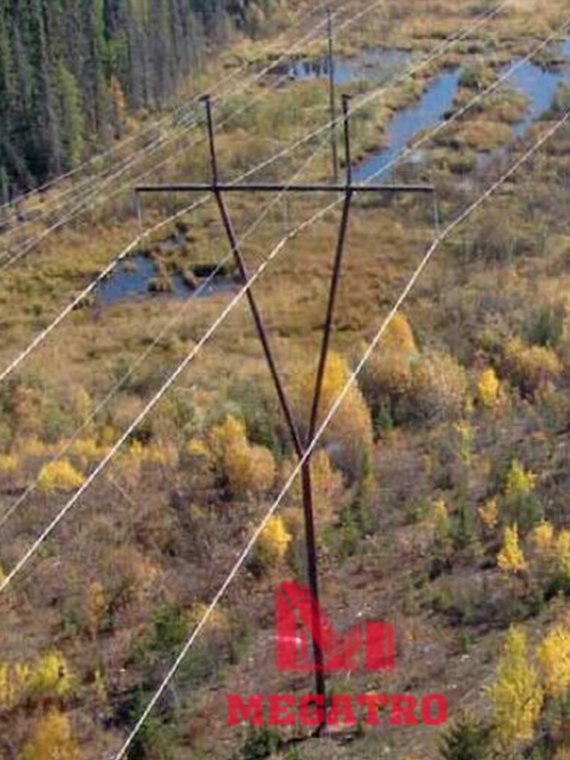

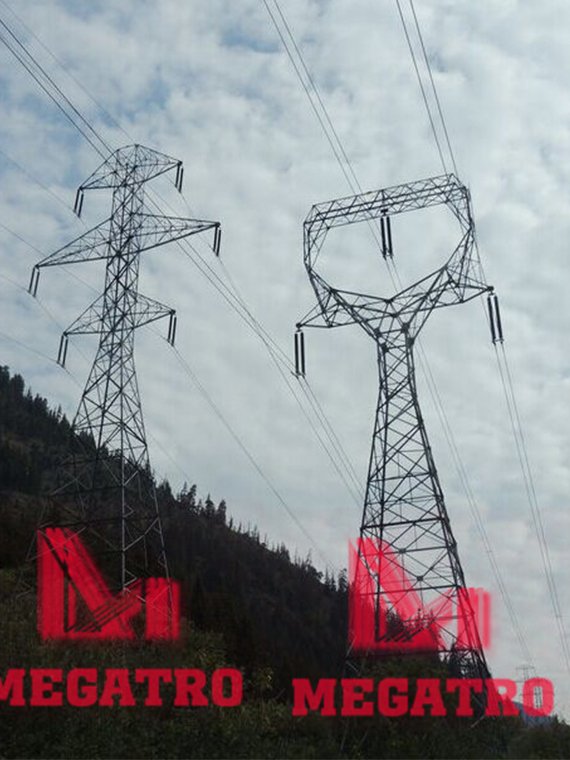

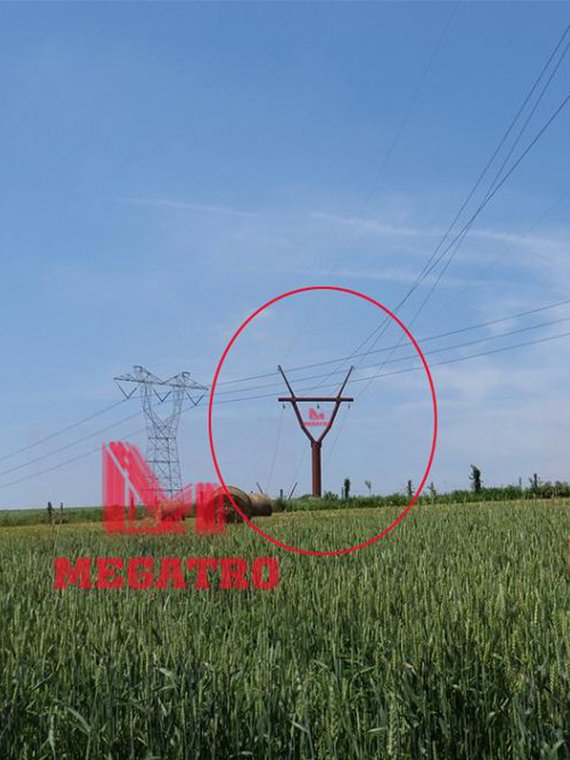

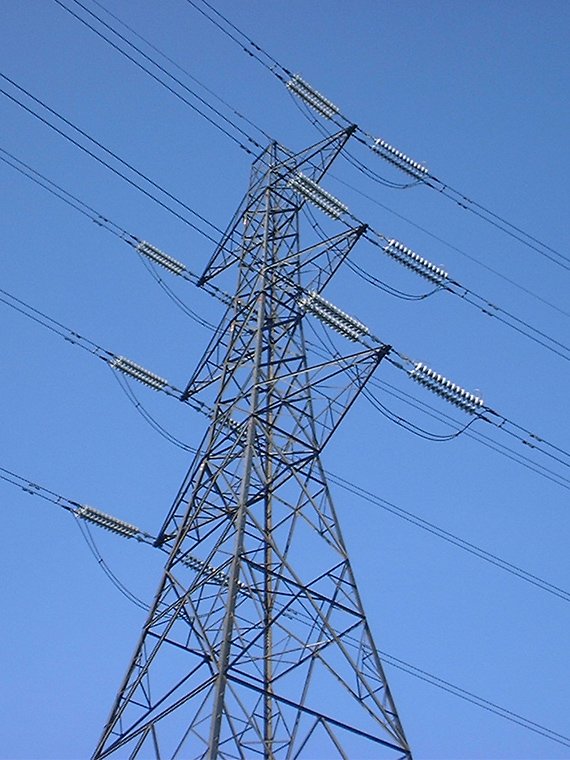

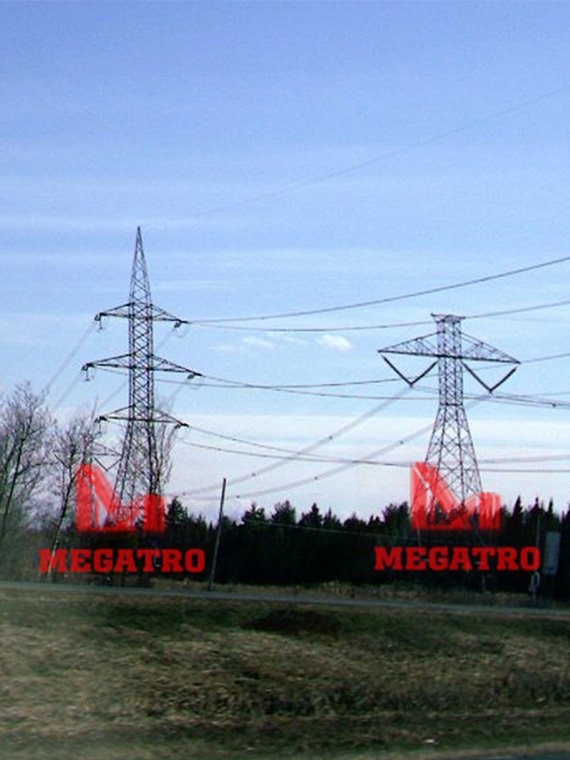

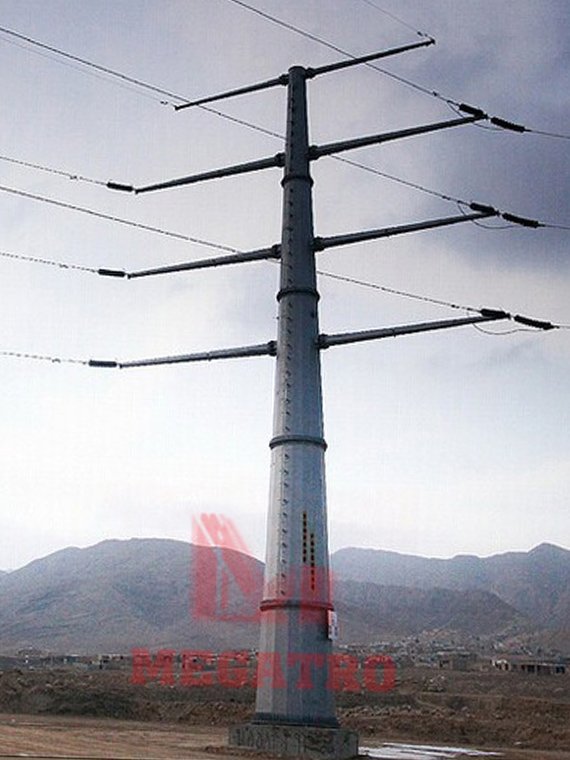

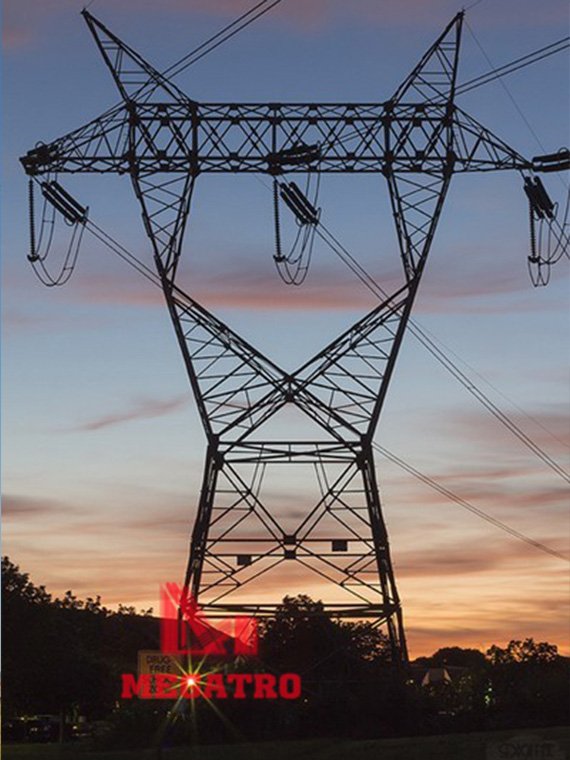

110KV single circuit OHL angle tower

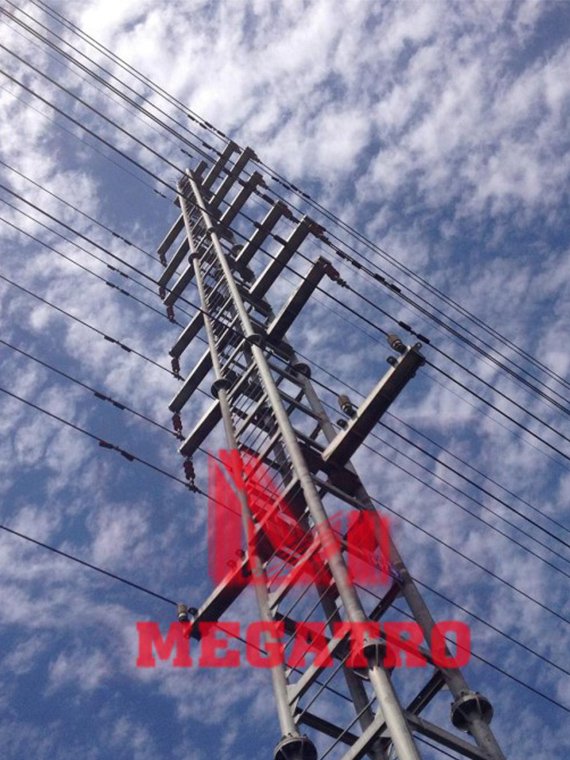

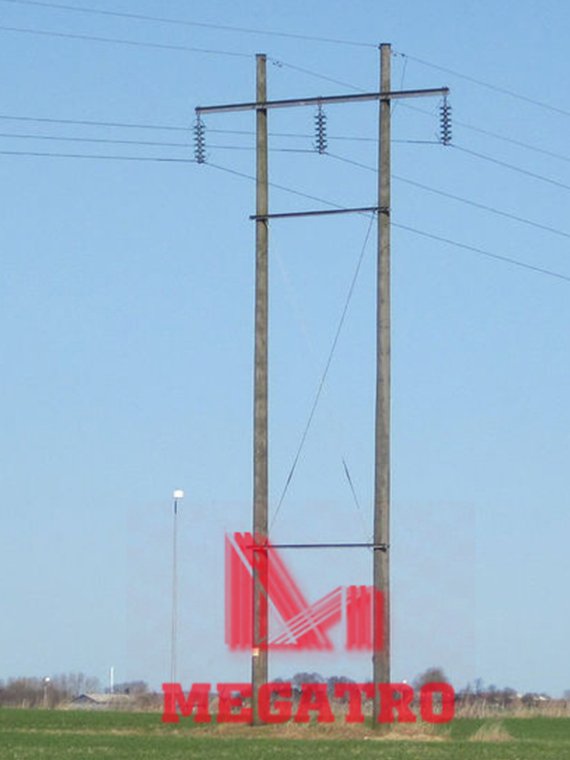

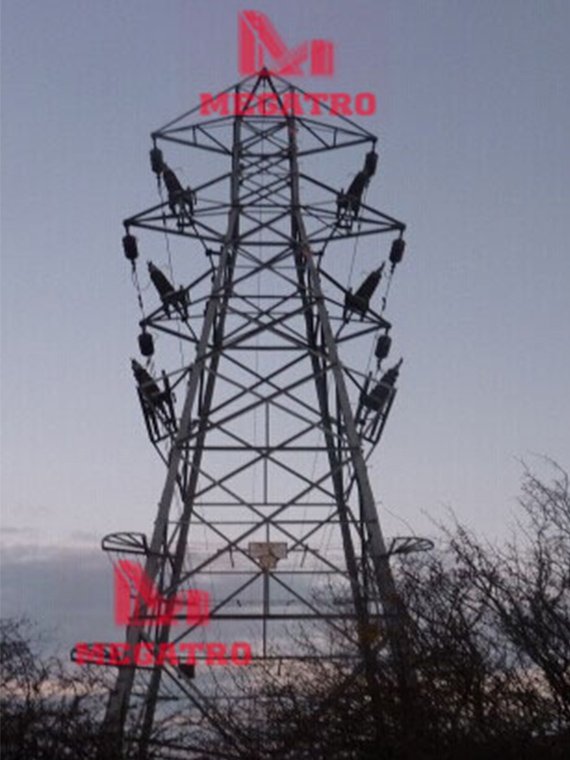

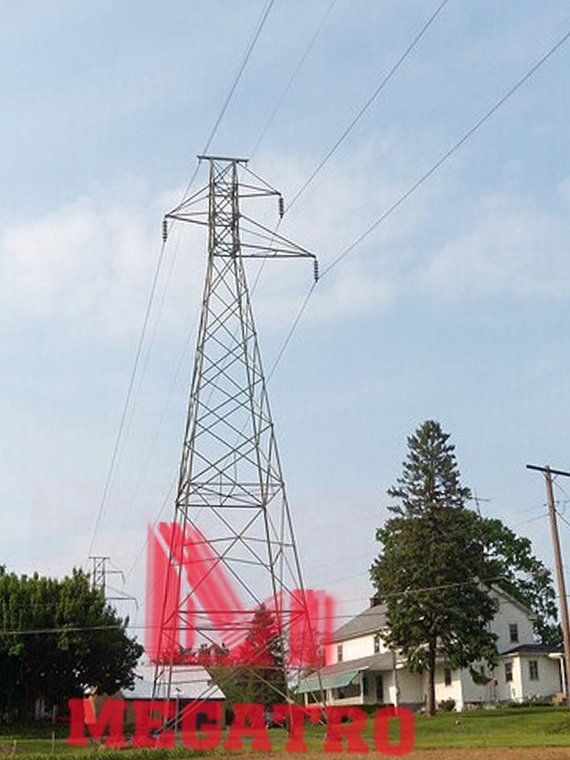

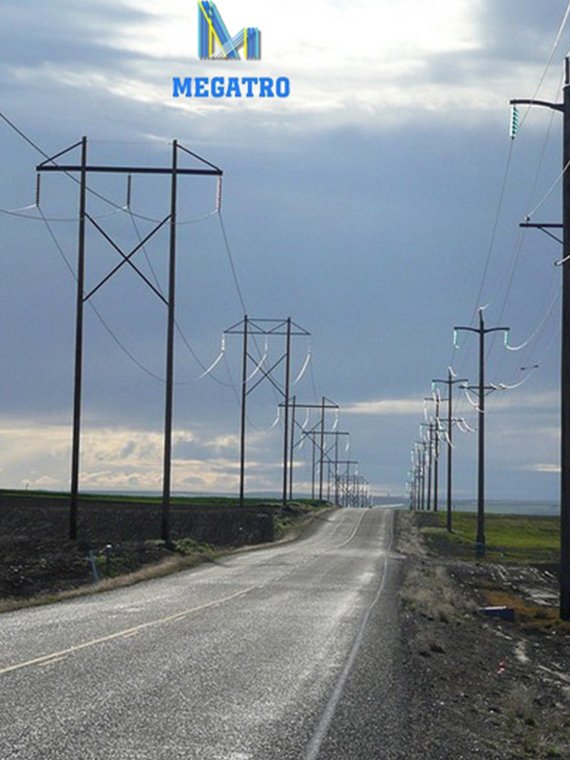

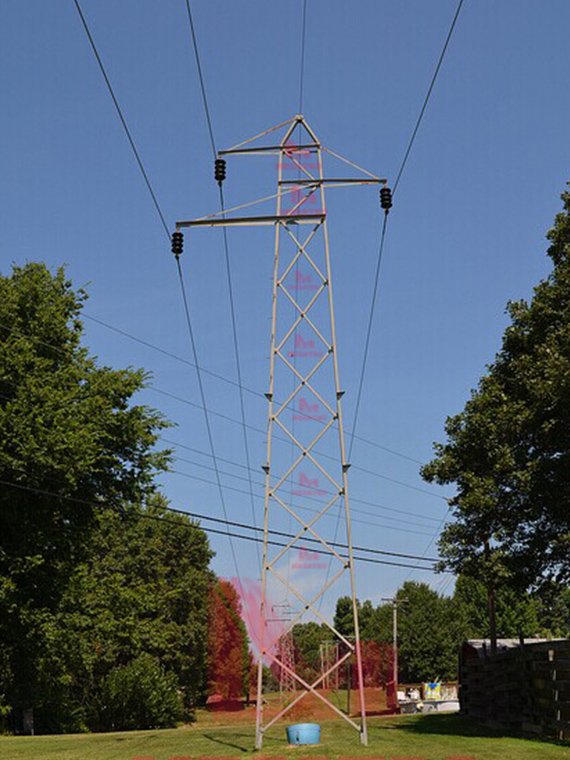

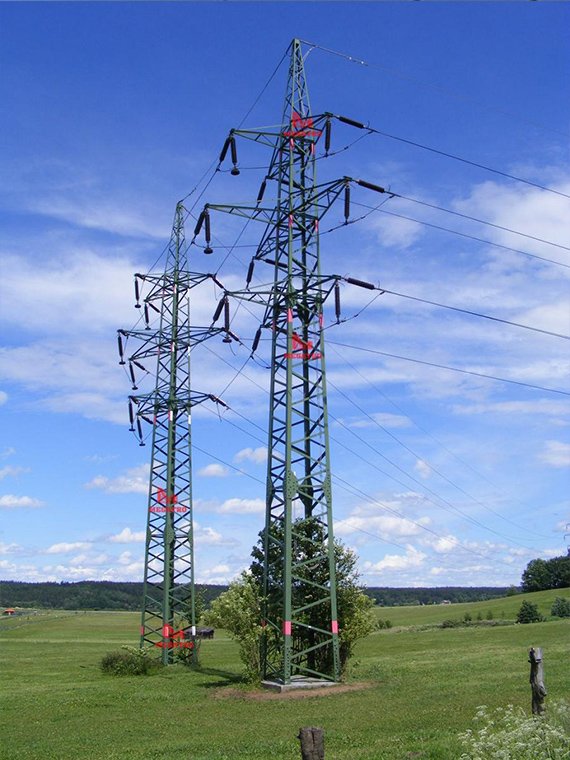

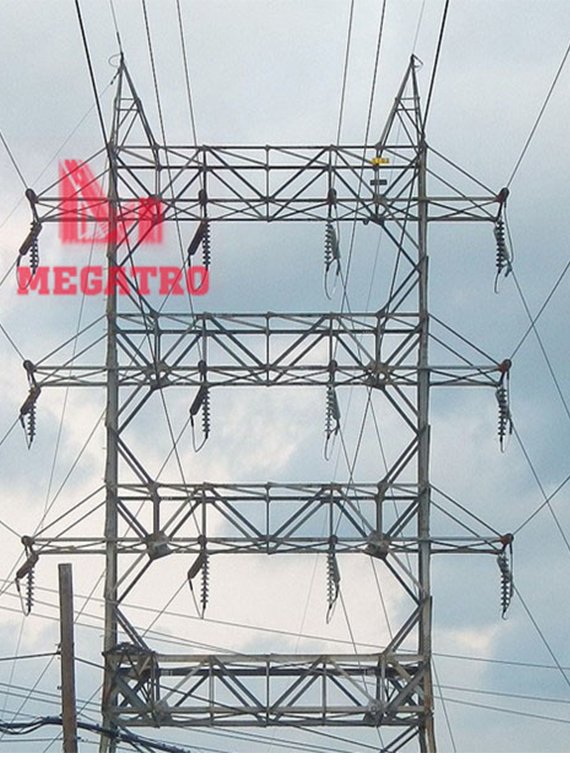

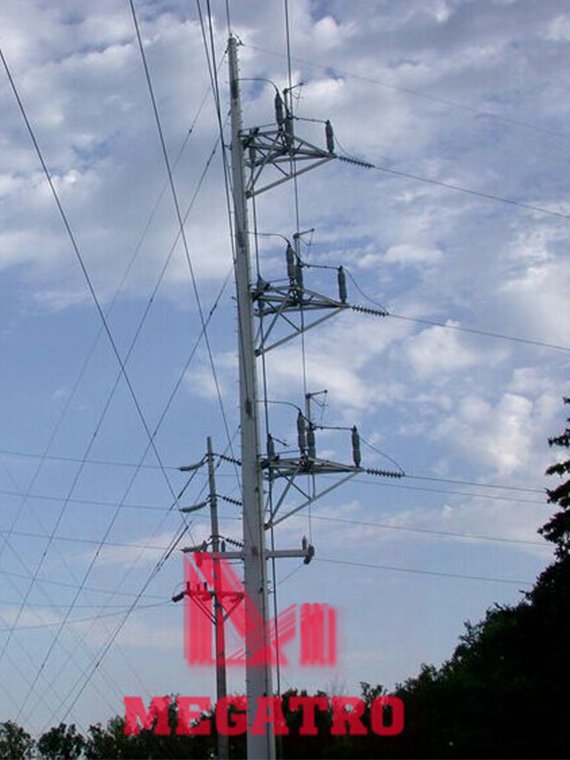

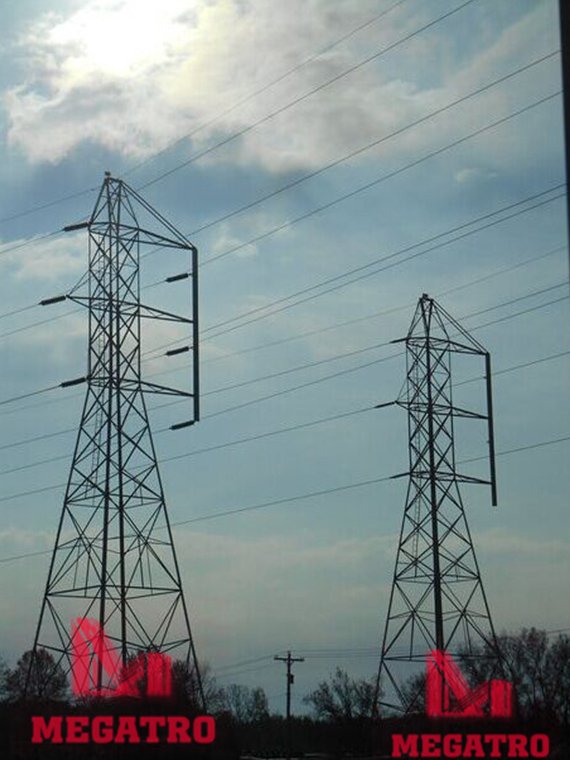

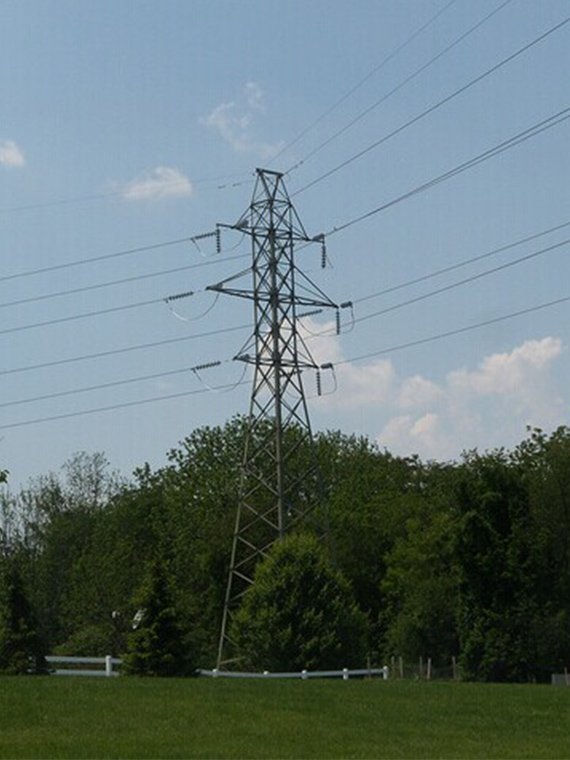

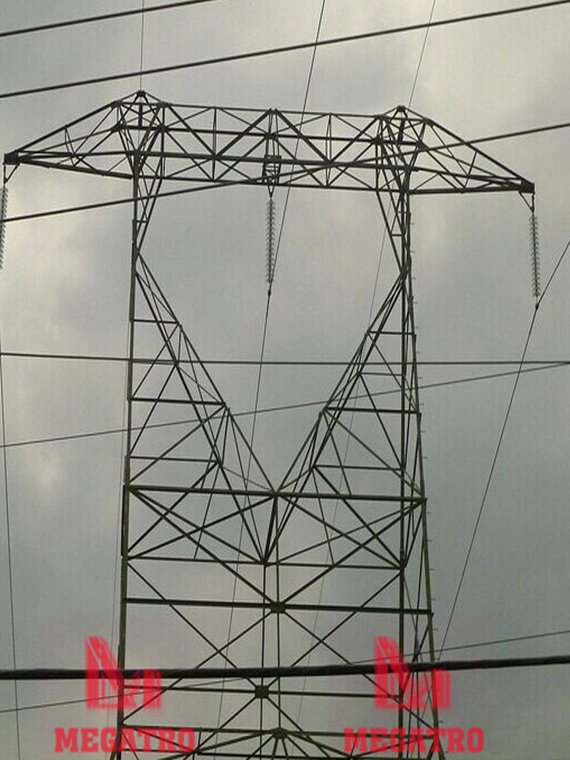

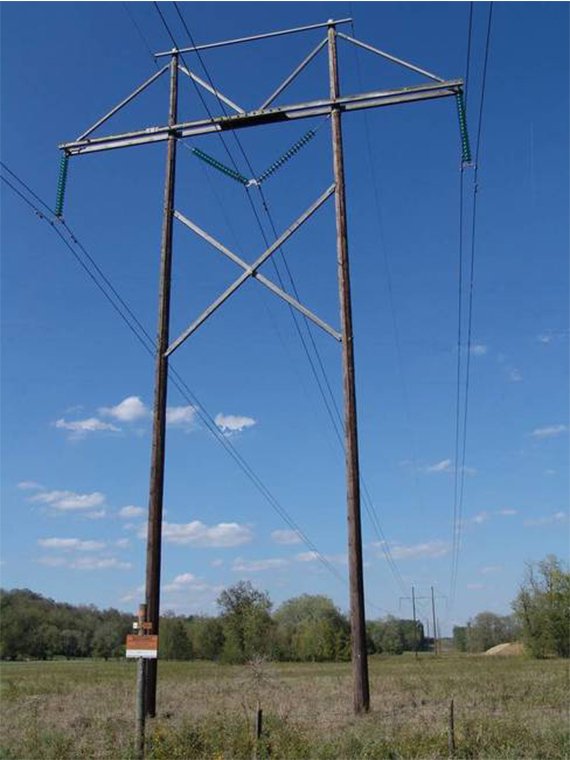

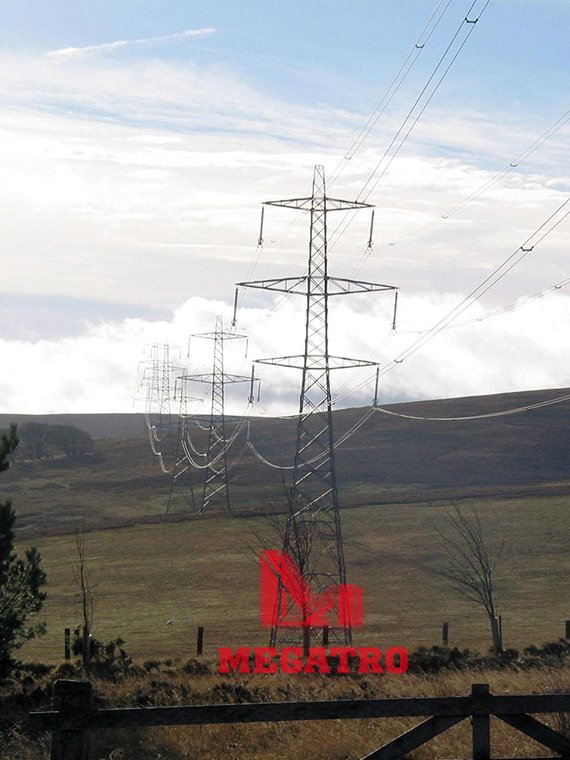

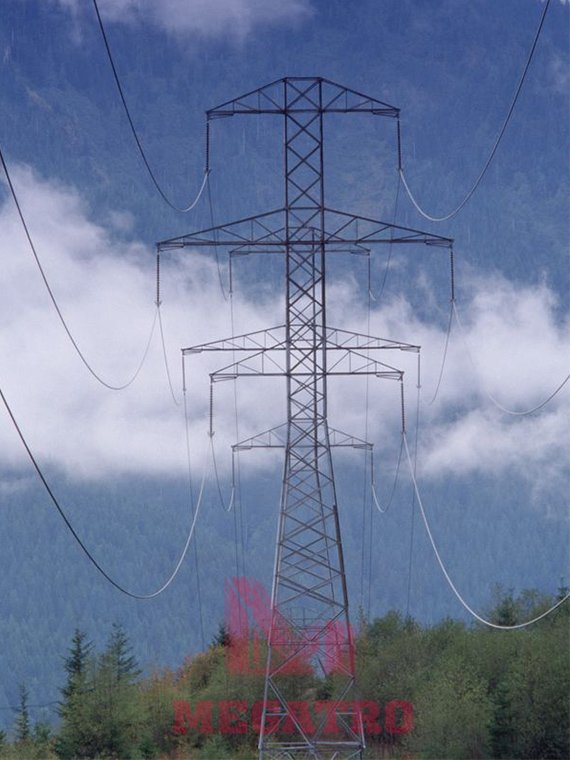

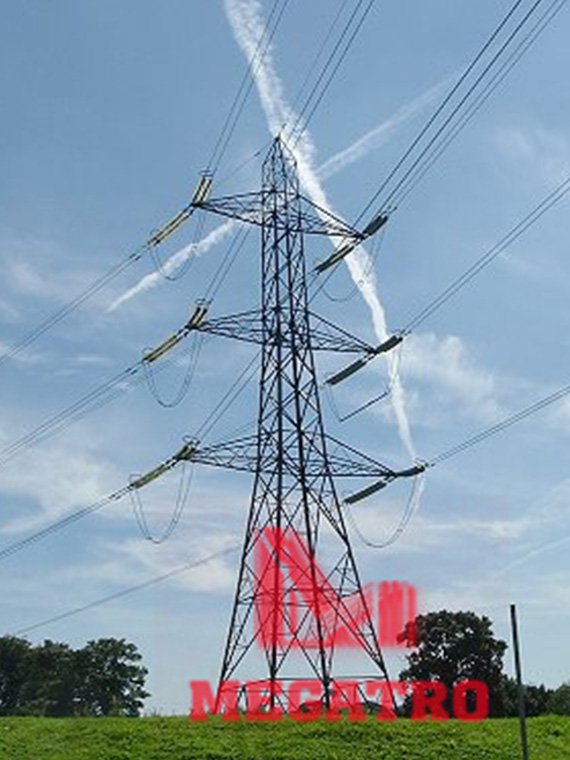

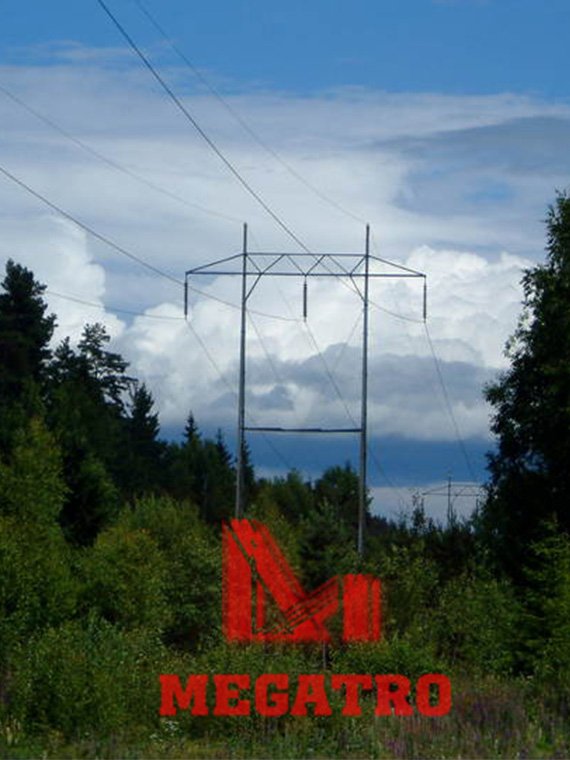

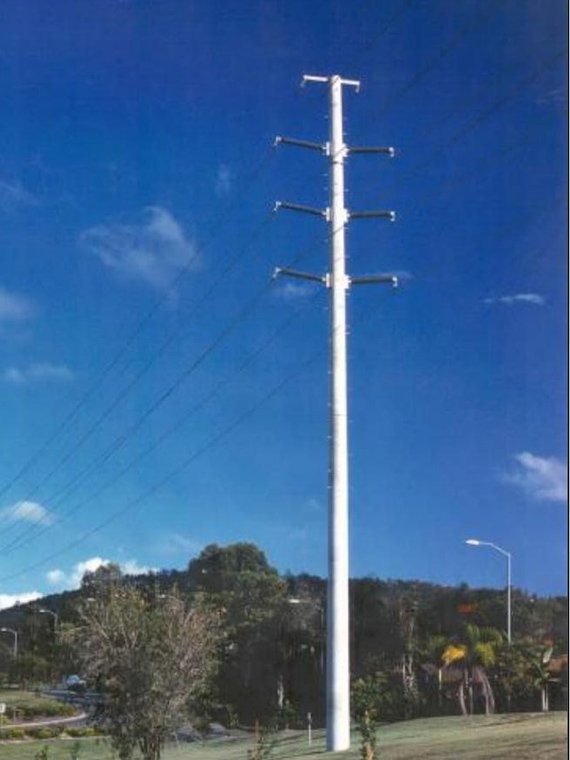

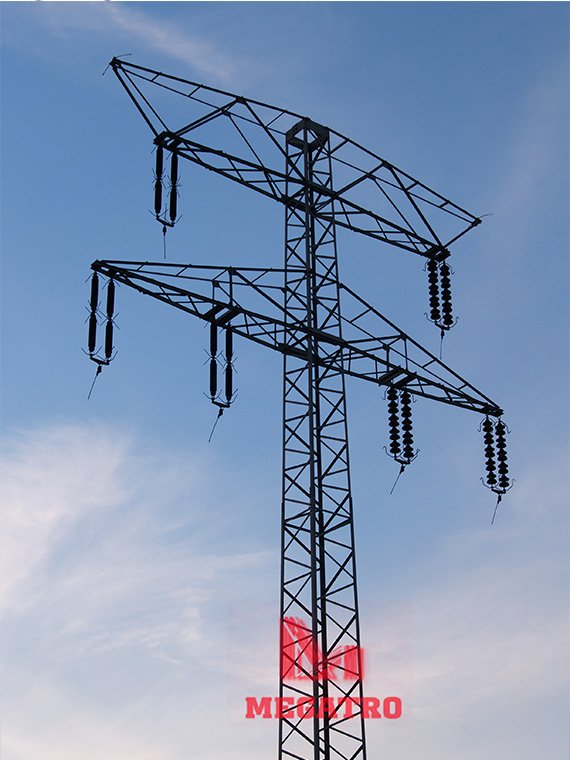

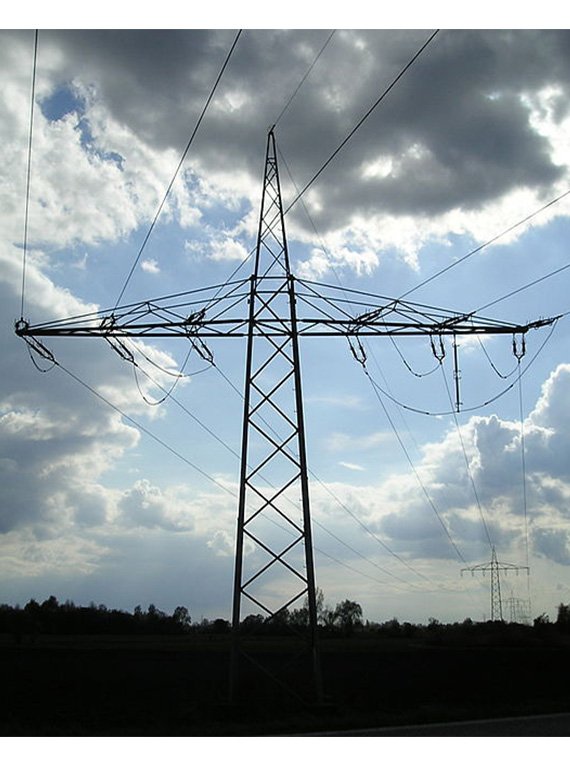

A single-circuit transmission line carries conductors for only one circuit. For a three-phase system, this implies that each tower supports three conductors. In single-circuit towers the conductors are lined up horizontally. Both tubular and lattice steel towers can be designed so as to support single-circuit of electrical current. Single-circuit towers hold the different conductors stacked atop one another, while in single-circuit towers the conductors are lined up horizontally.

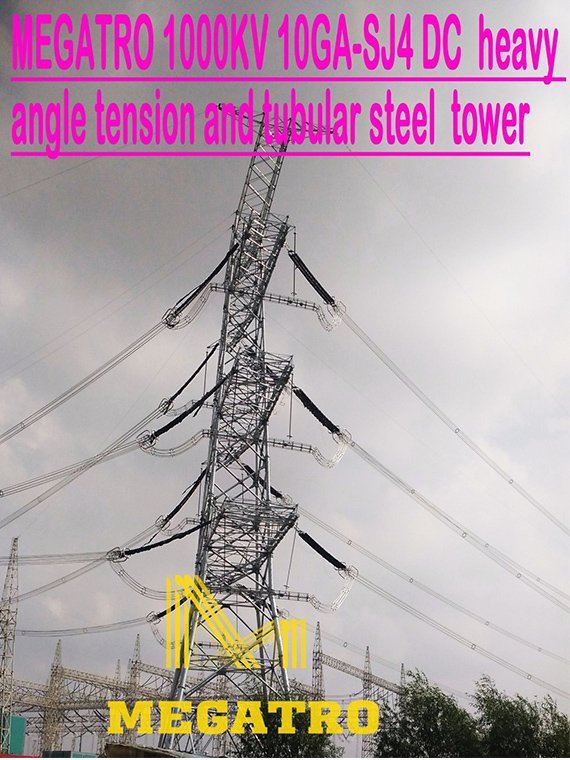

When in power transmission line project, we also need change line angle if project requirements. Then we have light angle tower, medium angle tower and heavy angle tower. This photo refers to our 110KV single circuit angle tower.

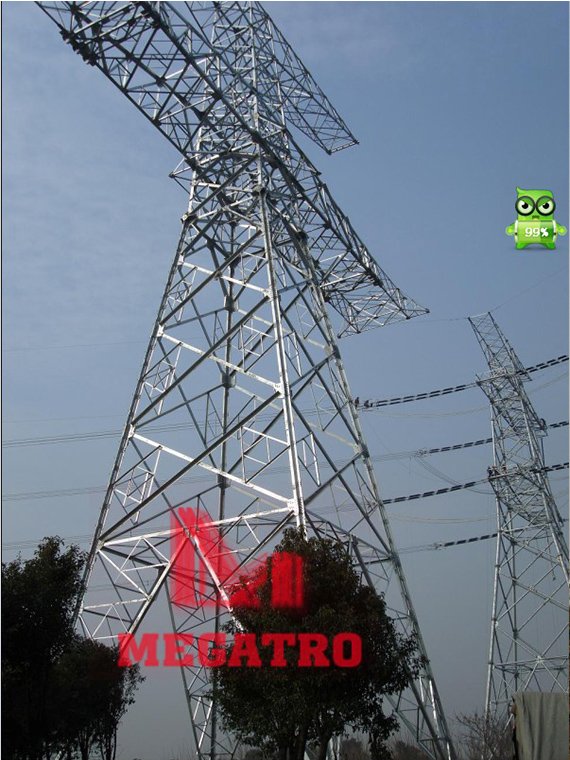

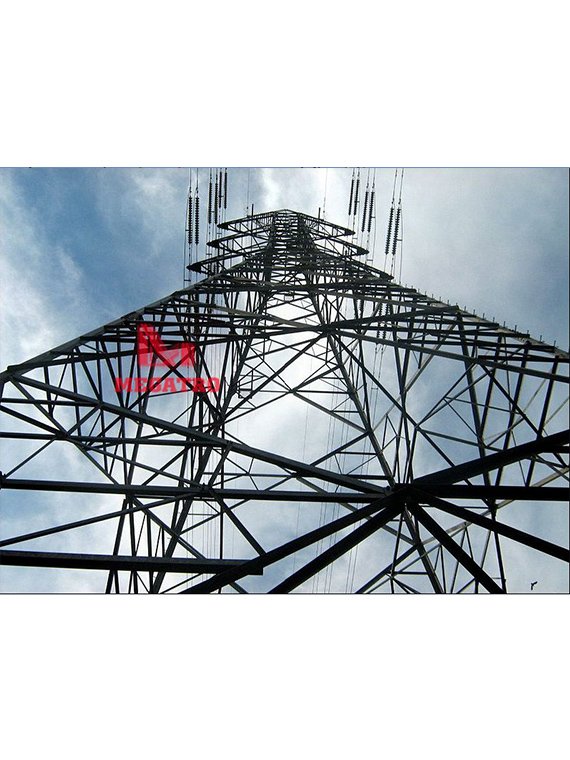

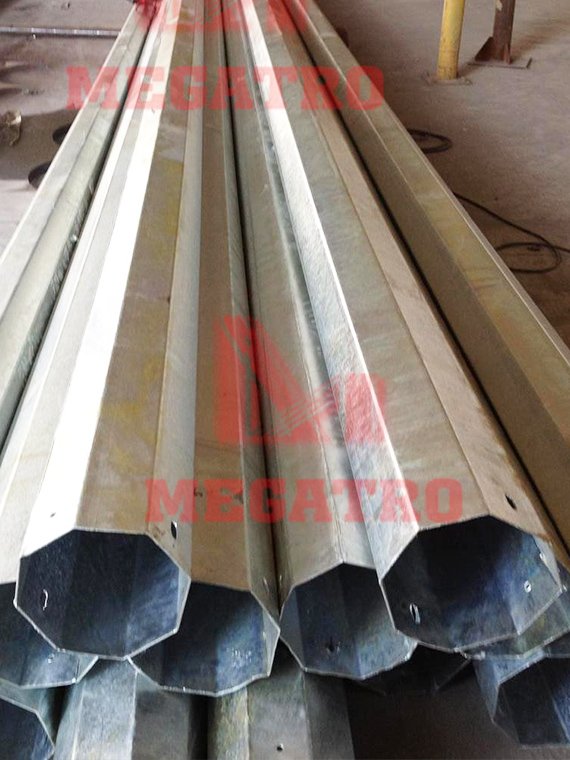

These tower legs are steel pipes, and bracing are angle steel, and connected by bolts. MEGATRO is equipped with sophisticated machinery and equipment for the manufacture of 110KV single circuit angle tower, we have skilled worker with certificated welders, and offers design for our clients. In material we often adopt mild steel (ASTM A36, Q235B, ST37, BS40B), high strength and lower alloy (ASTM A572 GR50, GR65, Q345B, Q345C, Q420, Q460, S355J0, S355JR , ST52, BS50 and equivalent materials).

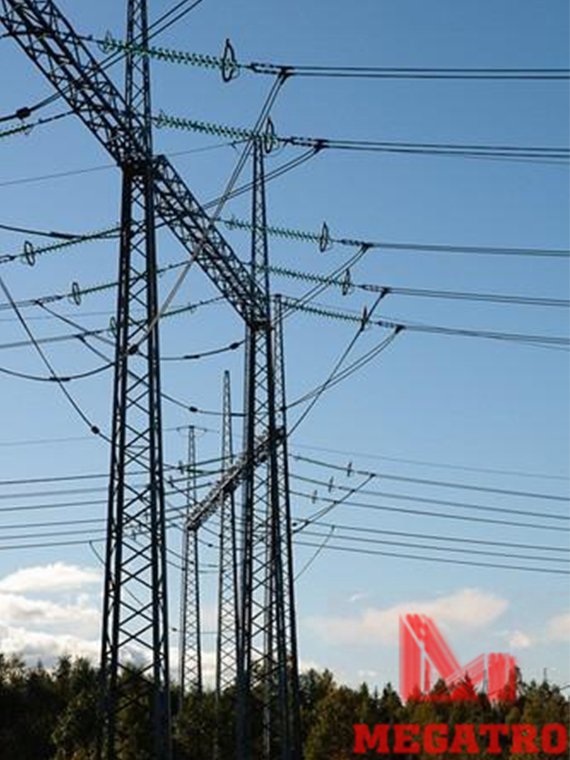

MEGATRO can optimized design and make transmission tower less weight, high strength, proper span distance, good wind resistance, and economy in the use of materials. Our main design engineer from USA, can use PLS/TOWER software to design every type steel tower based on structural calculations and geometrical frame drawings. To meet the expectation, we produce shop drawings, components list and full production documentation, and even complete 3D models that facilitate the elimination of all design and drawings errors generated on the drawings. Another advantage is our 3D design and loading & design report, and can optimized the design and save cost for our clients.

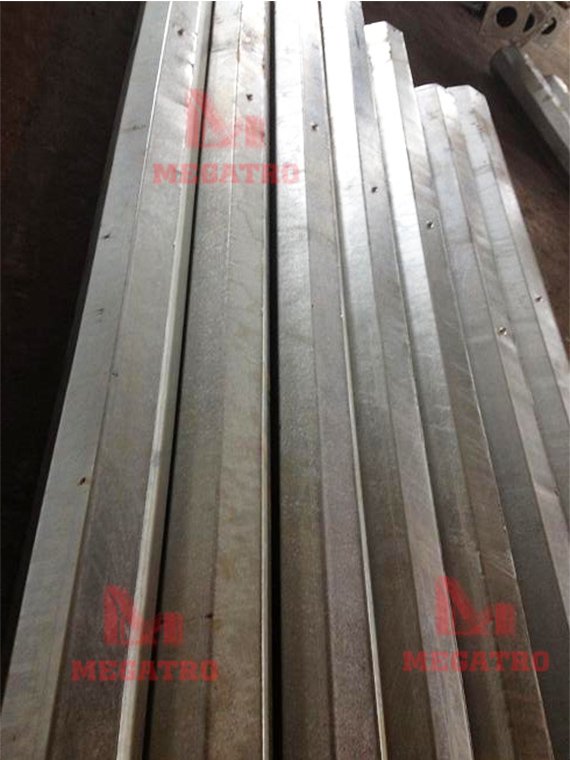

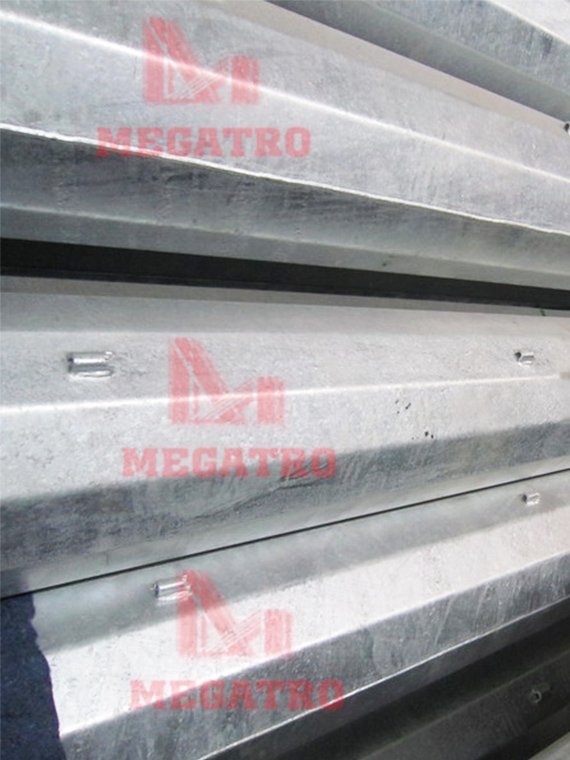

After fabrication all 110KV single circuit angle tower, are delivered to the galvanizing facility to be Hot DIP Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. These strict procedures insure years of maintenance free.

Other information:

Availability size: Based on the customer's requirements.

Material: Chinese material or as per clients requirement

Package: Both parties discuss before delivery

Port of Loading: Qingdao Port

Lead Time: One month or based on the customer's needs

Minimum order: 1ton

Fabrication standard: Chinese Standard or other standard which client accepted

Steel grades

Tower legs: Chinese steel Q345B, which same to ASTM A572 GR50

Other webs, bracing and not stress plate and angle steel: Chinese Q235B, which same to ASTM A36

Plates: Chinese steel Q345B, which same to ASTM A572 GR50

Bolts: Chinese grade 6.8 and 8.8, which similar to ASTM A394

A) Dimension and tolerance for angle are according to GB/T1591-1994, similar to EN 10056-1/2

B) Hot dip galvanization in accordance with GB/T 13912-2002, which similar to ASTM A 123

C) The welding will be performance in accordance with AWS D1.1 or CWB standard

If any special requirement, we can design and discuss with client.