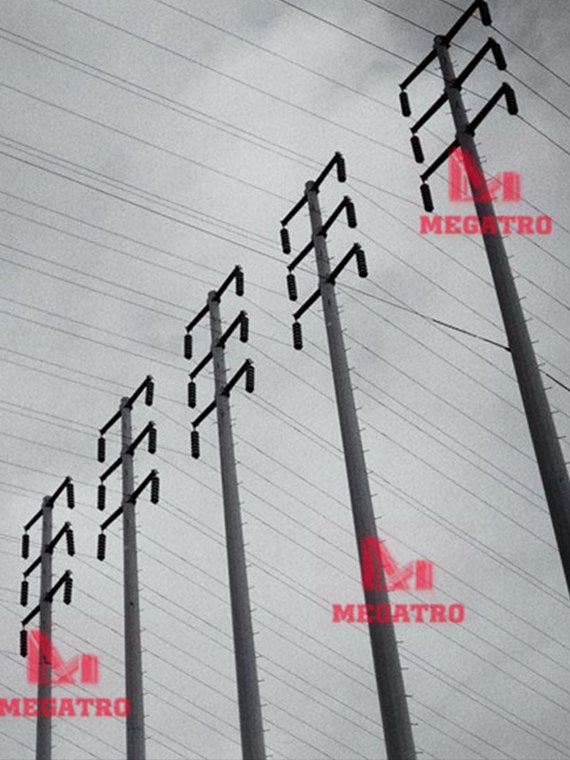

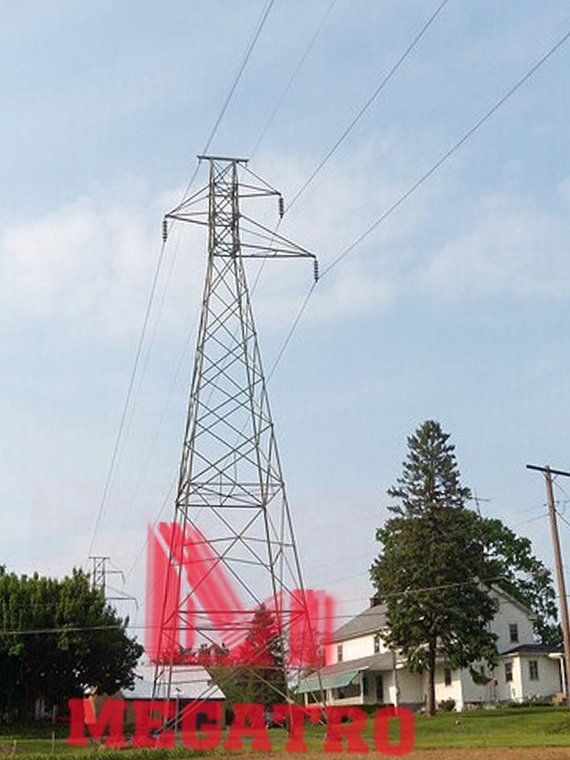

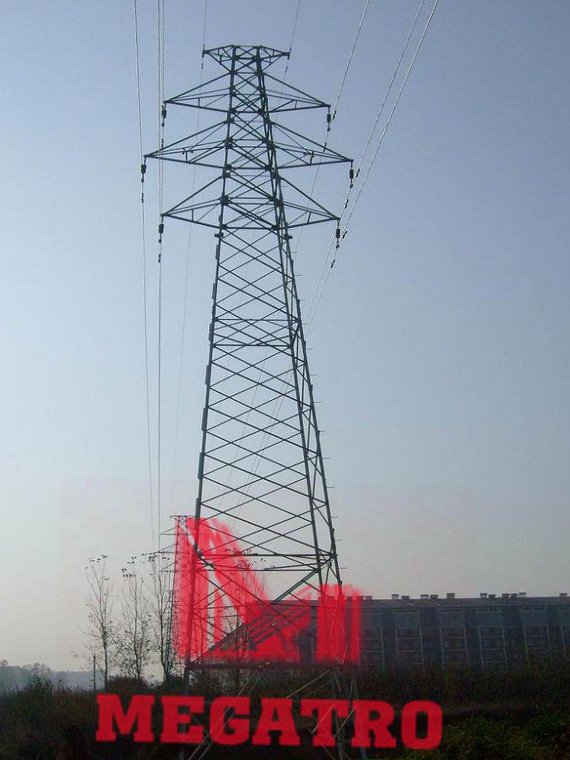

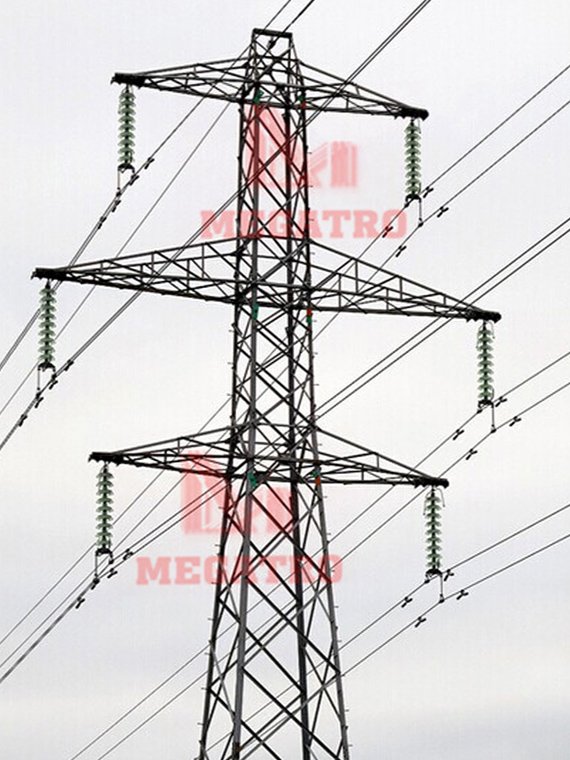

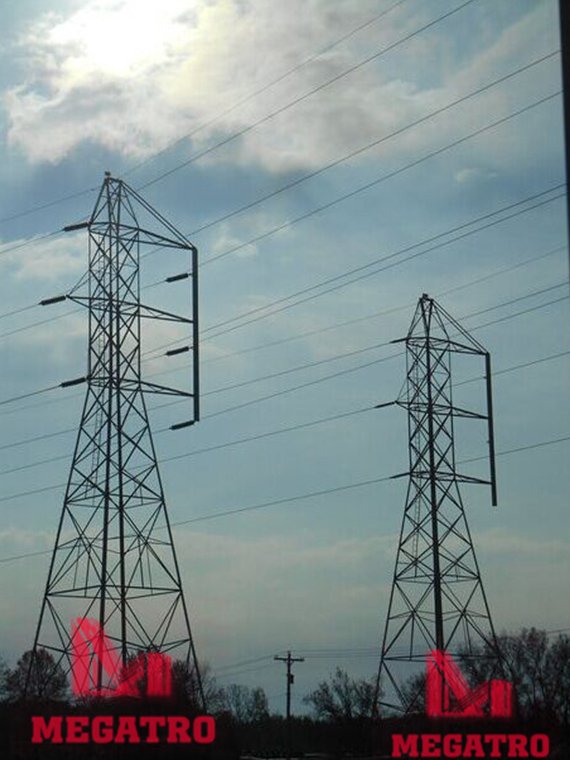

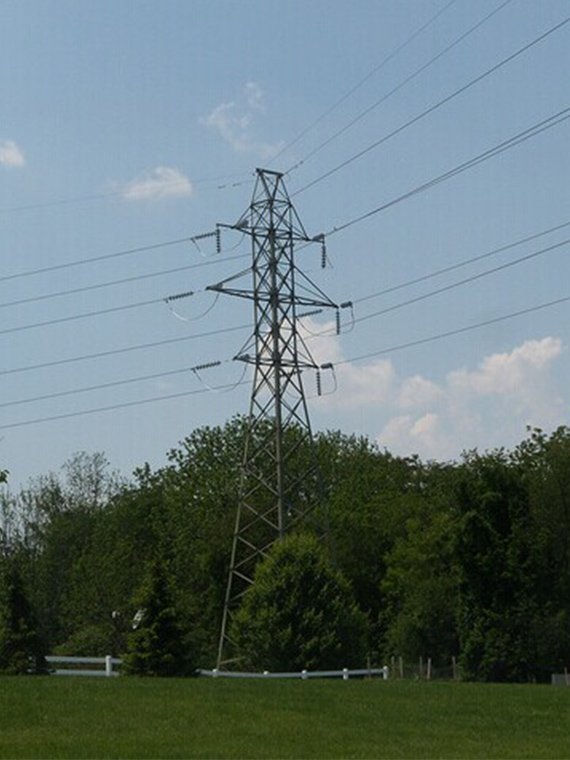

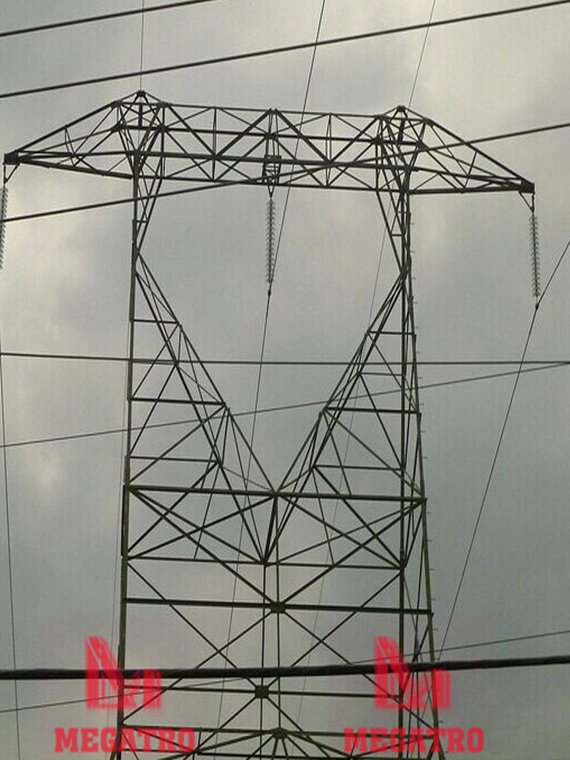

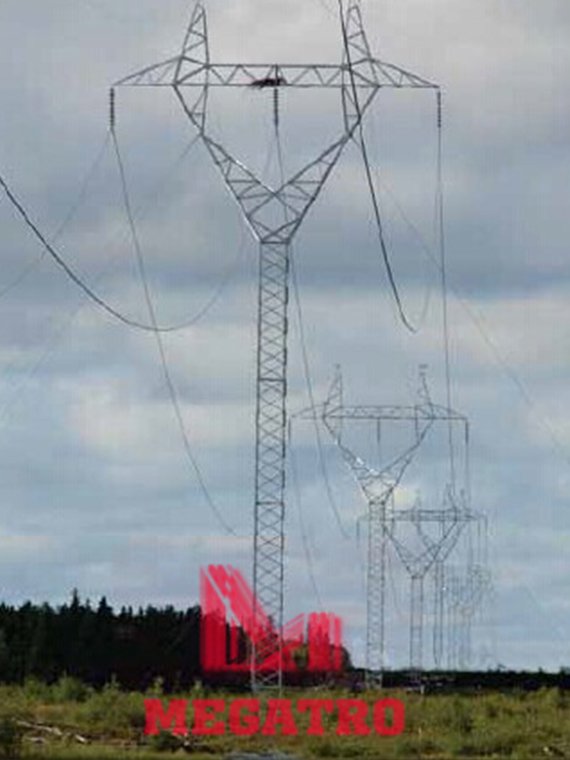

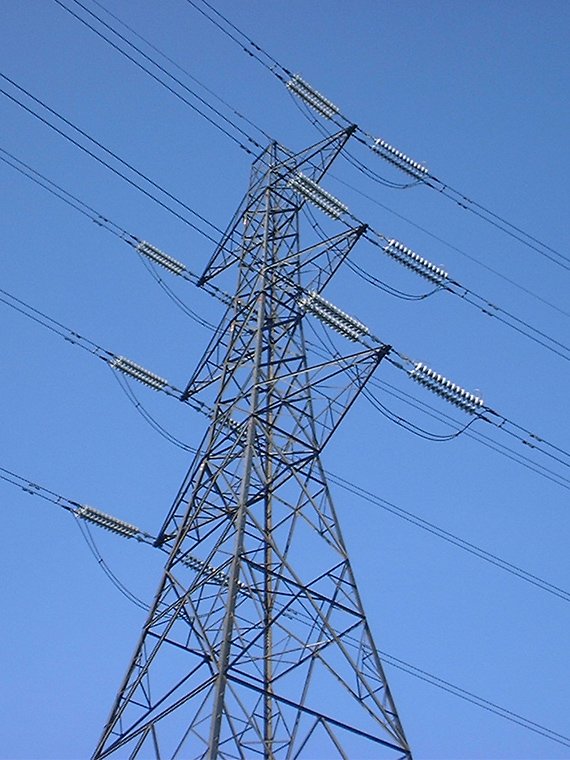

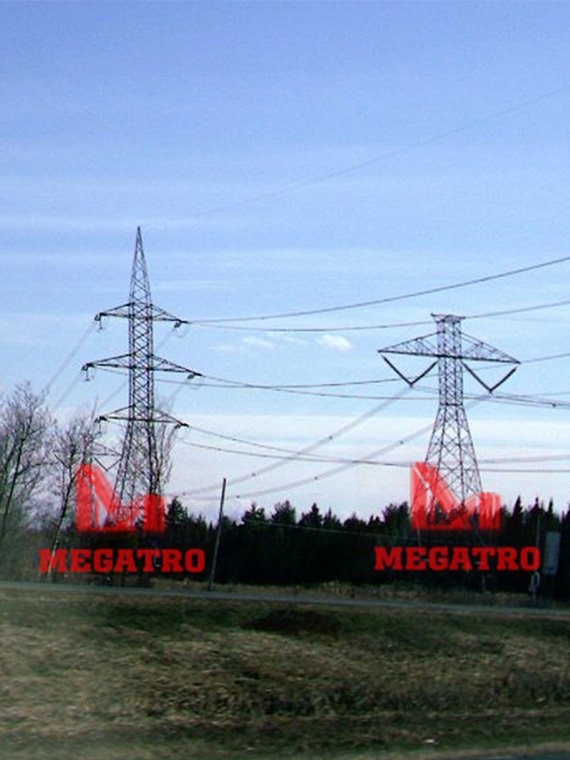

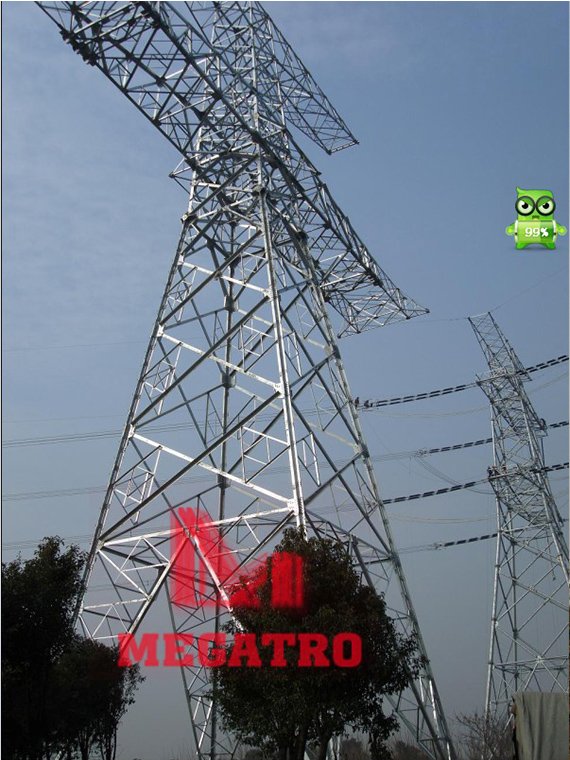

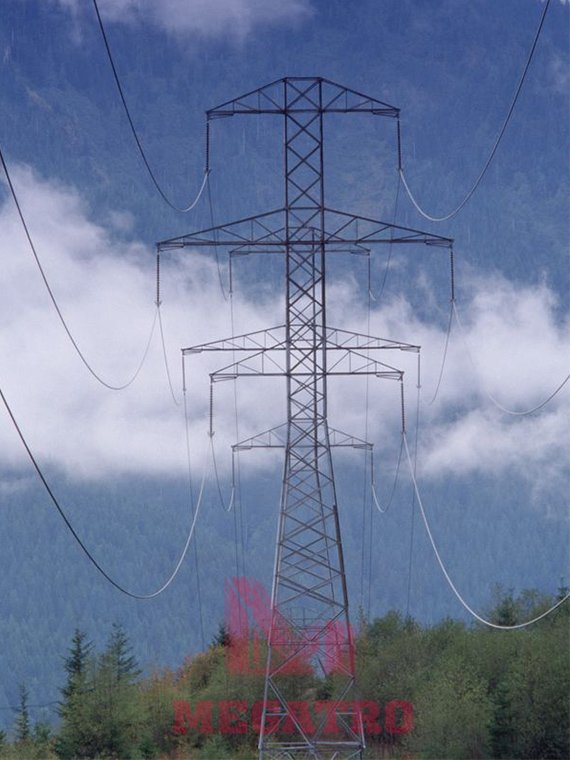

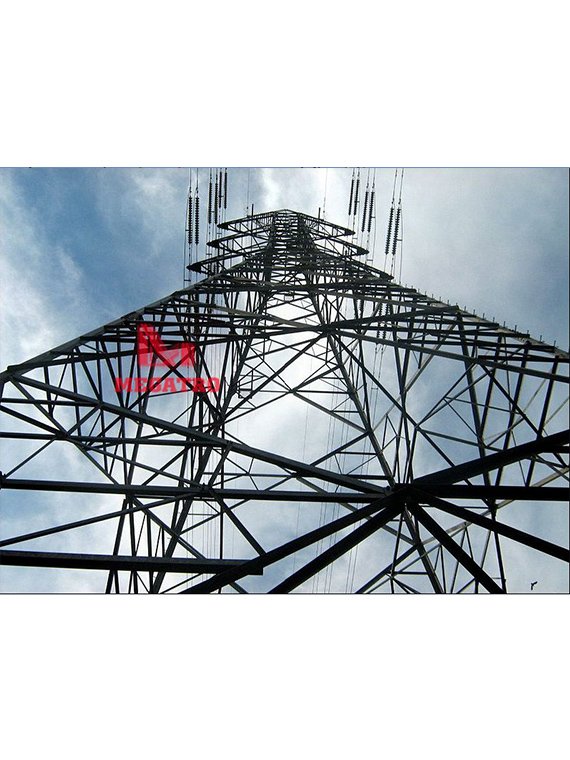

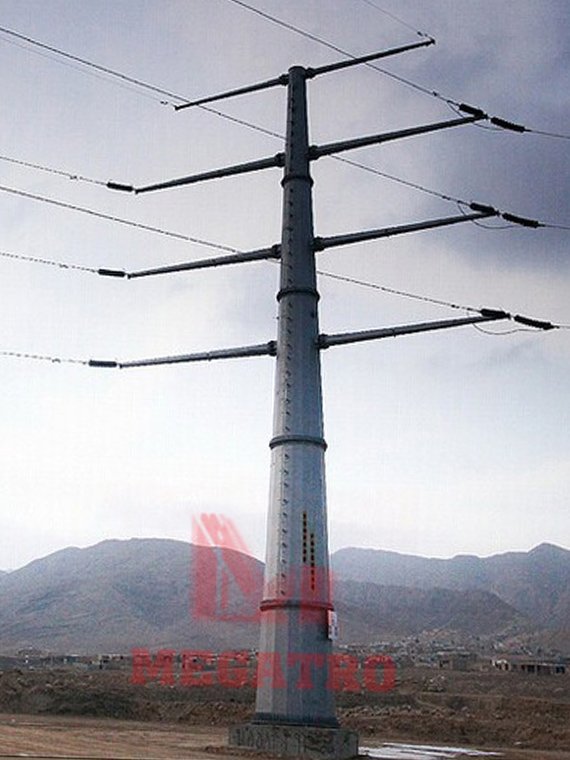

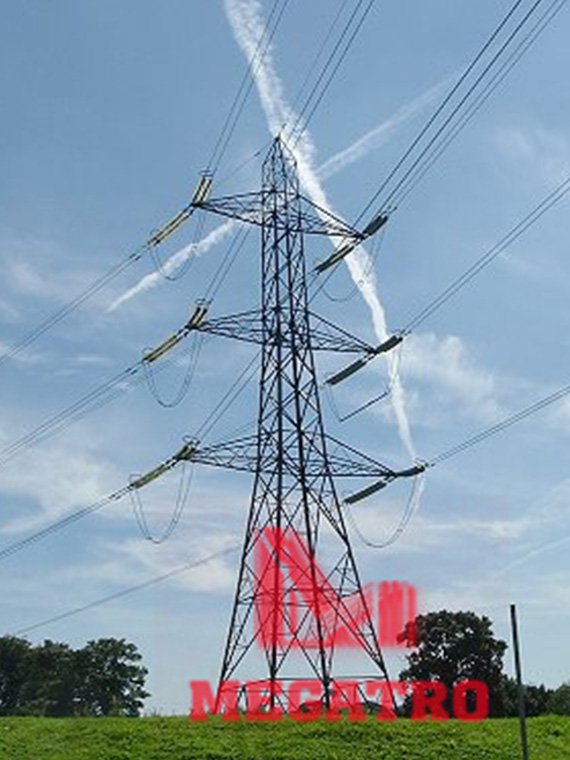

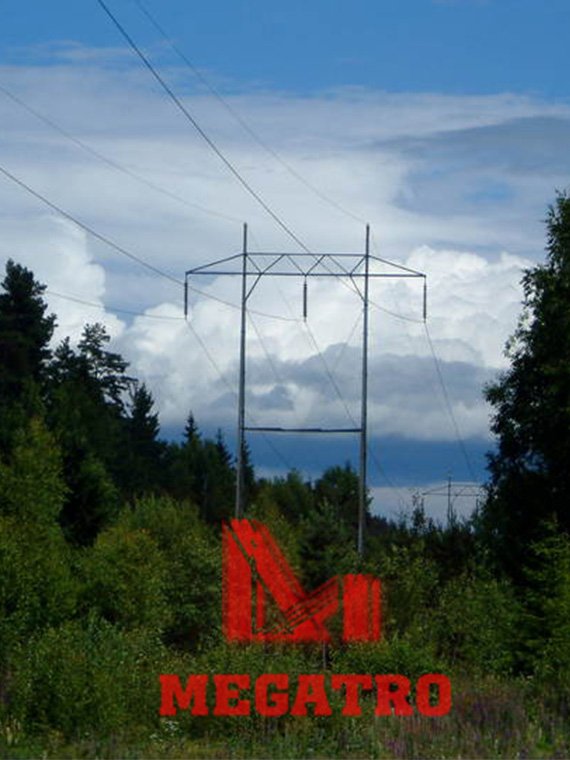

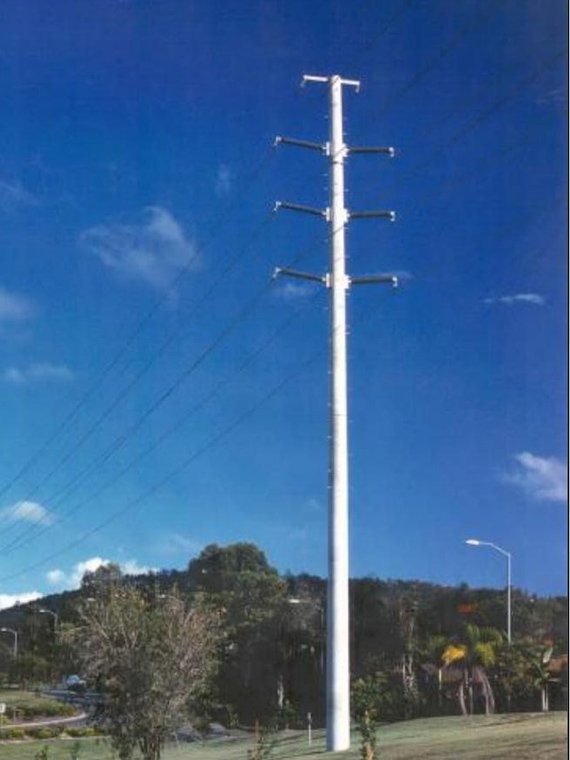

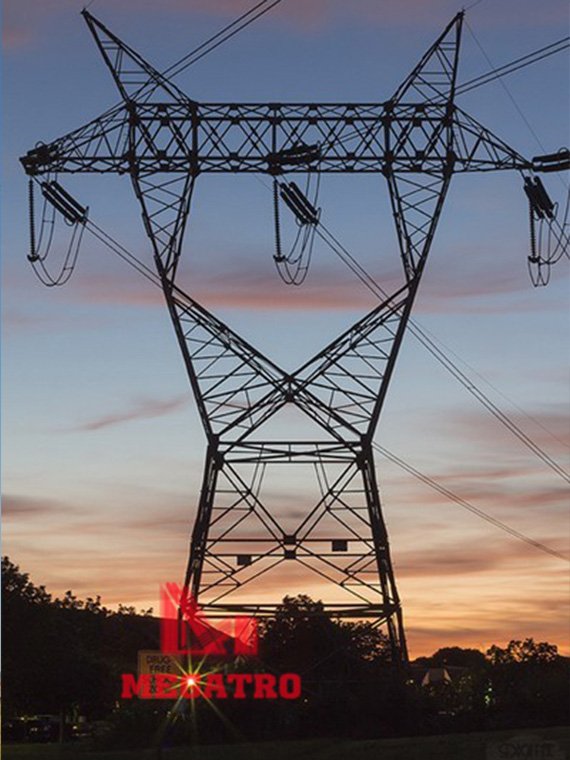

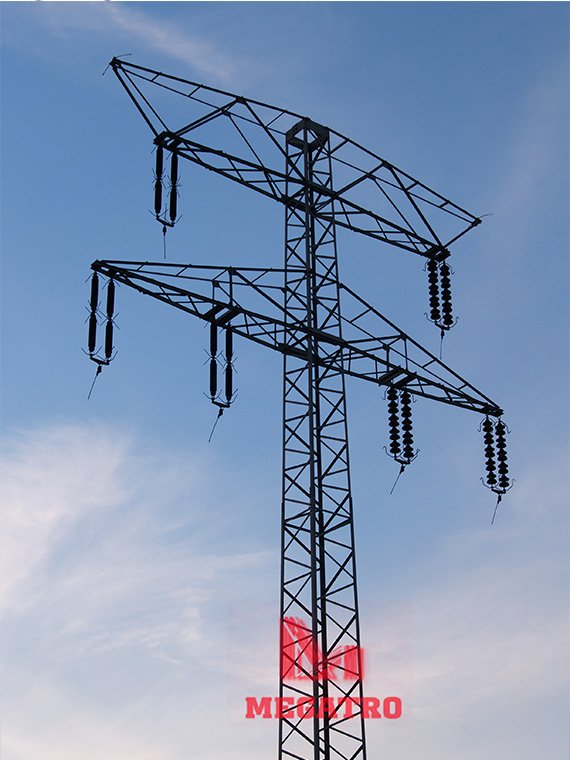

138KV transposition lattice tower structure

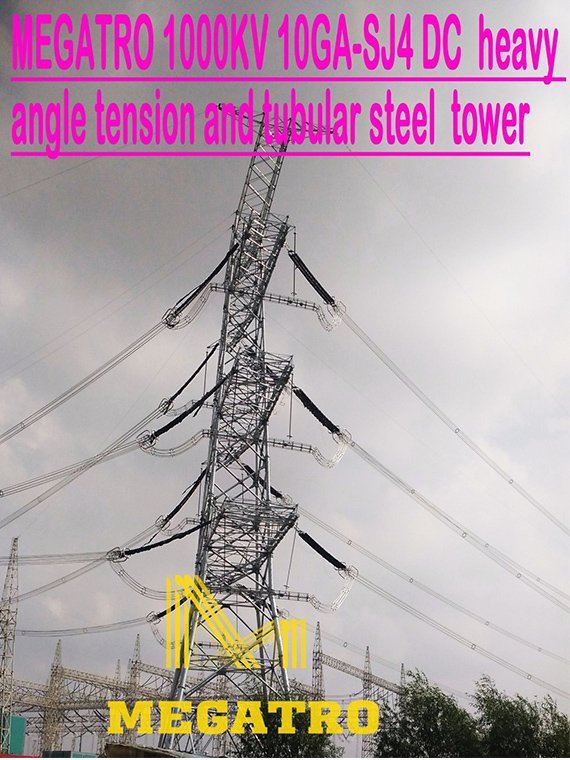

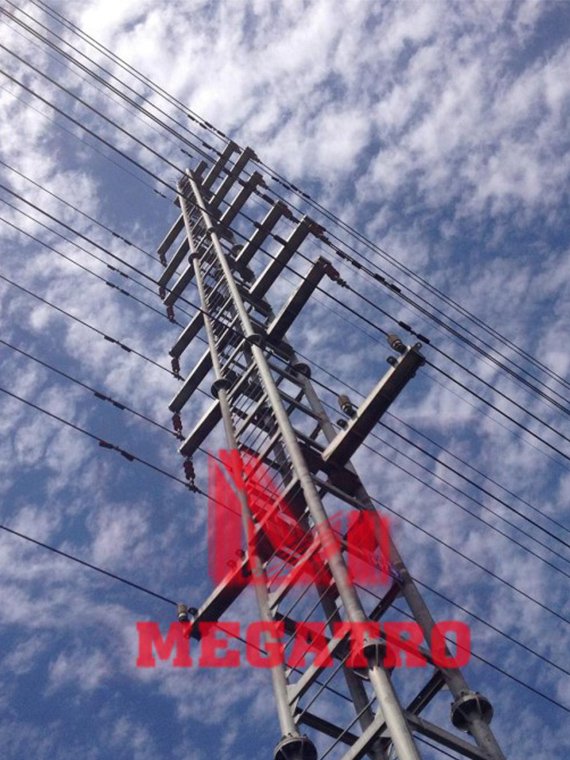

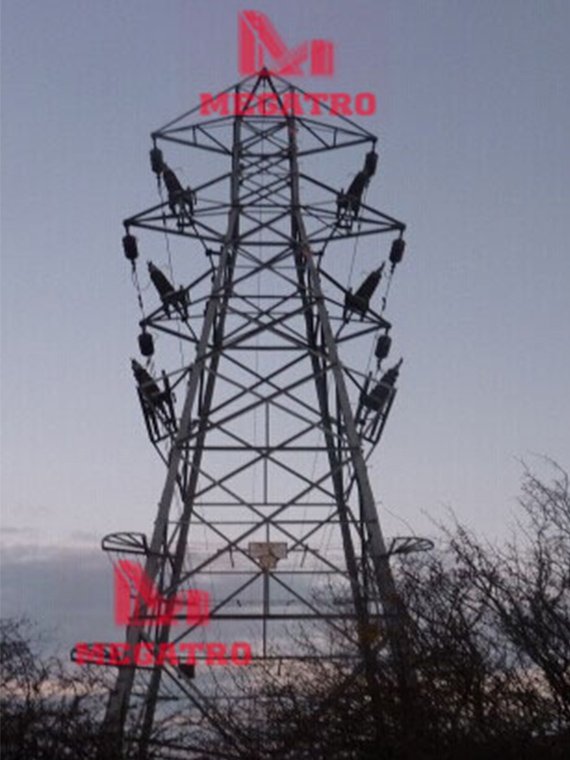

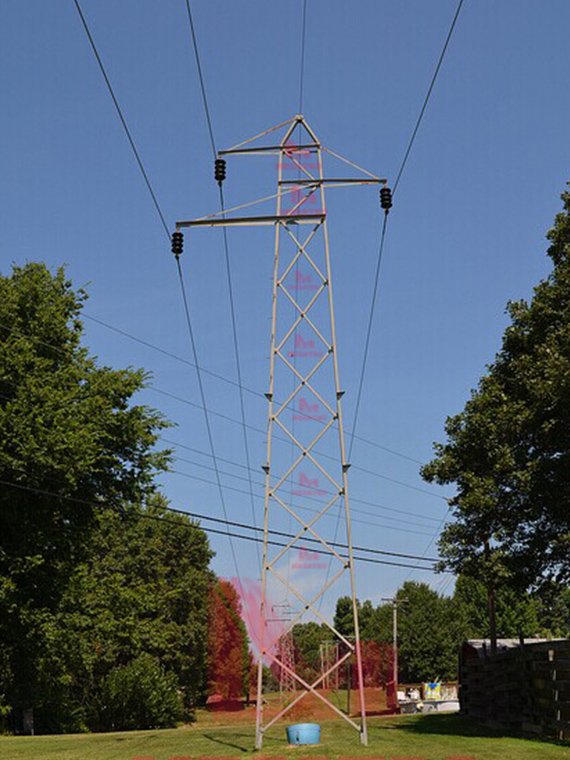

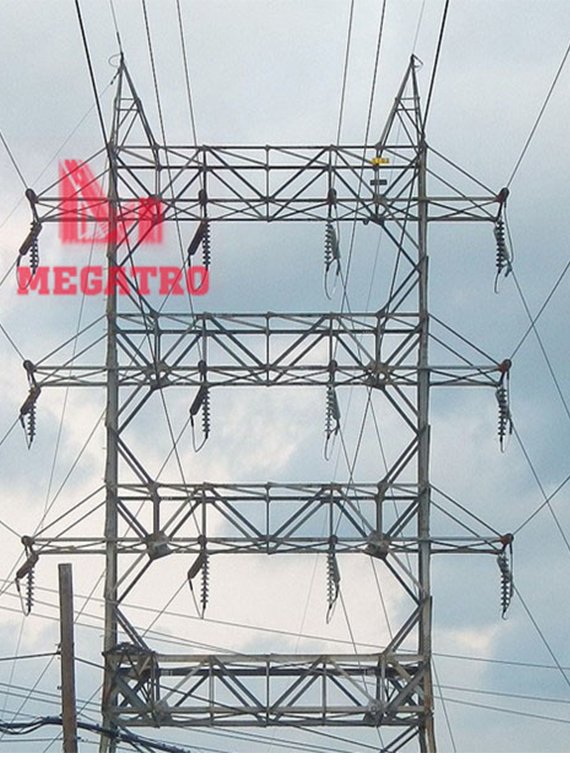

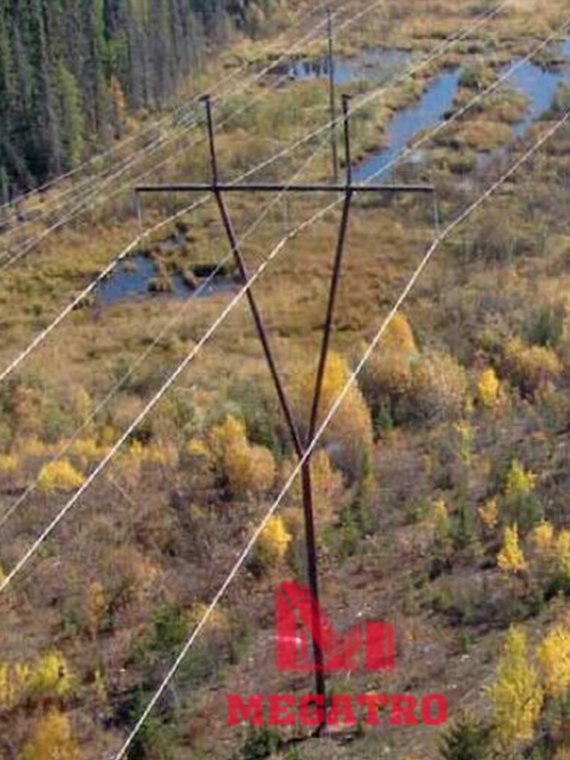

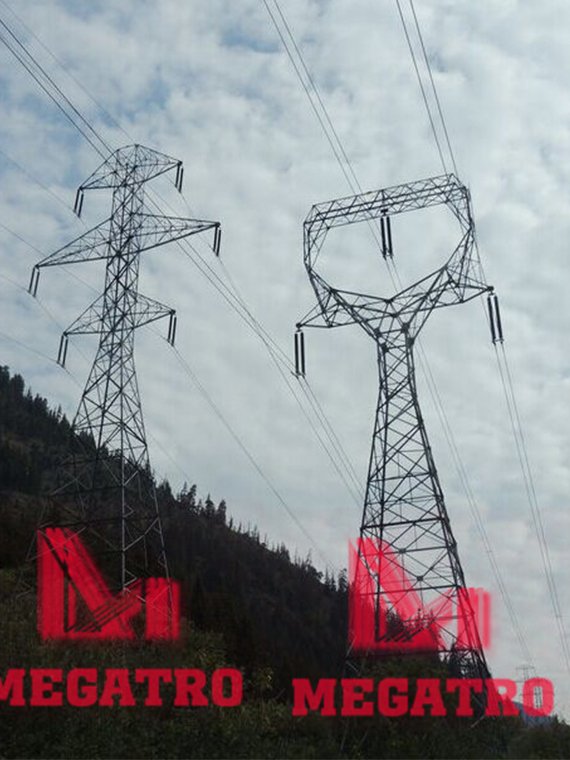

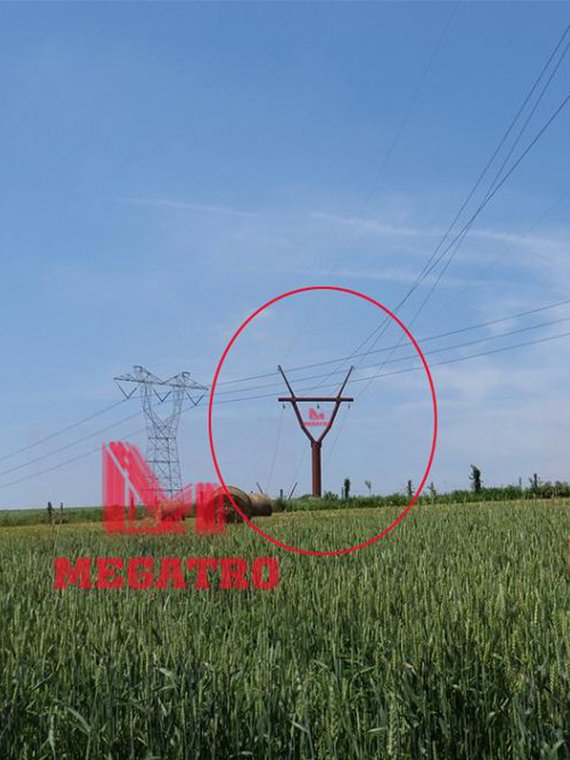

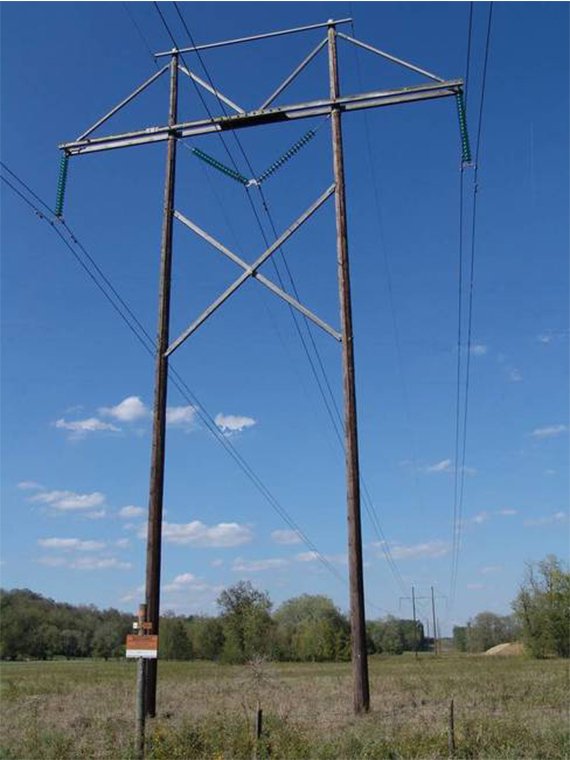

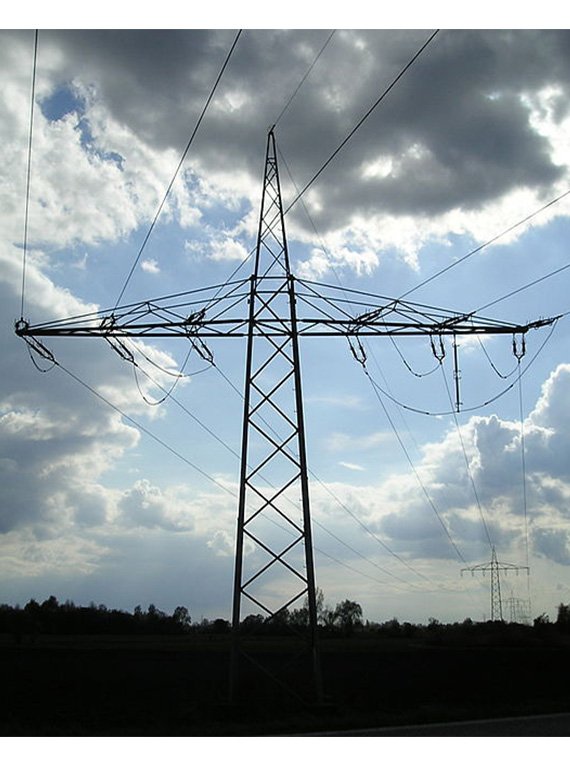

Transposition tower is a transmission tower that changes the relative physical positions of the conductors of a transmission line. For example, a section of a line may be (top-to-bottom) phases A-B-C on the left, also phases C'-B'-A' on the right. The next section may be B-C-A on the left, also A'-C'-B' on the right. A transposition tower allows these sections to be connected together, while maintaining adequate clearance for the conductors. This is important since it balances electrical impedances between phases of a circuit. This photo refers to our 138KV transposition lattice tower structure.

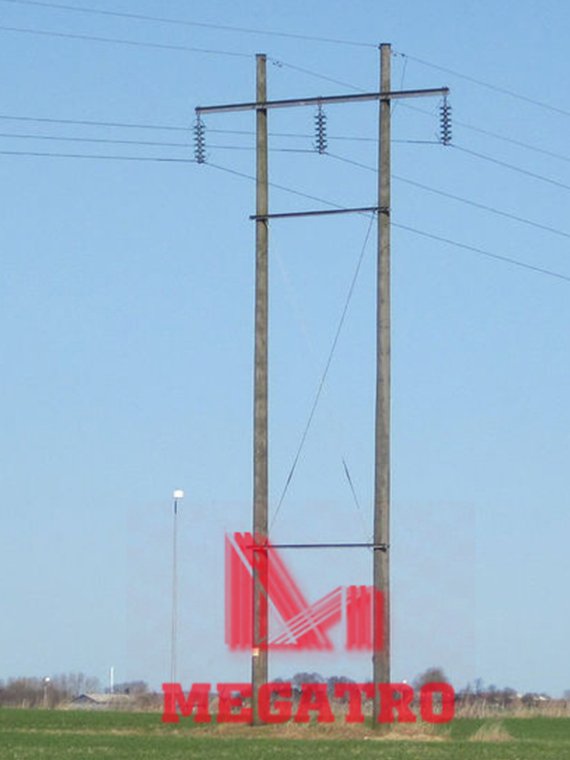

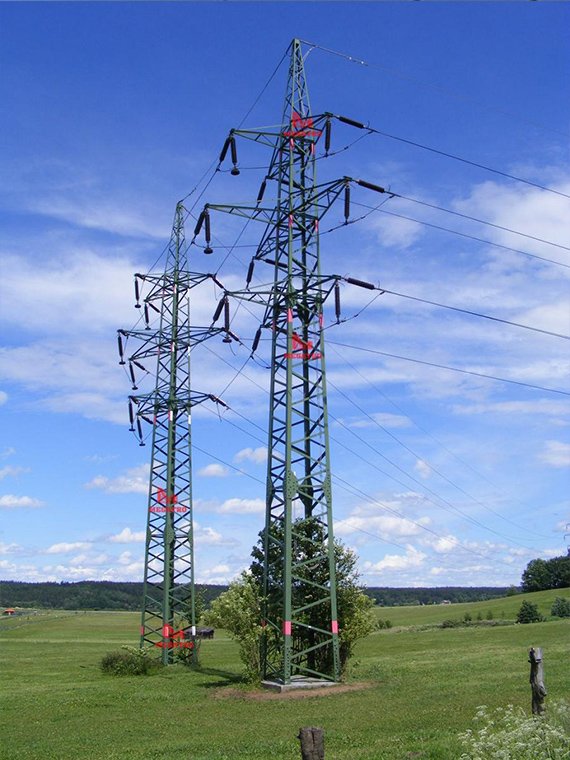

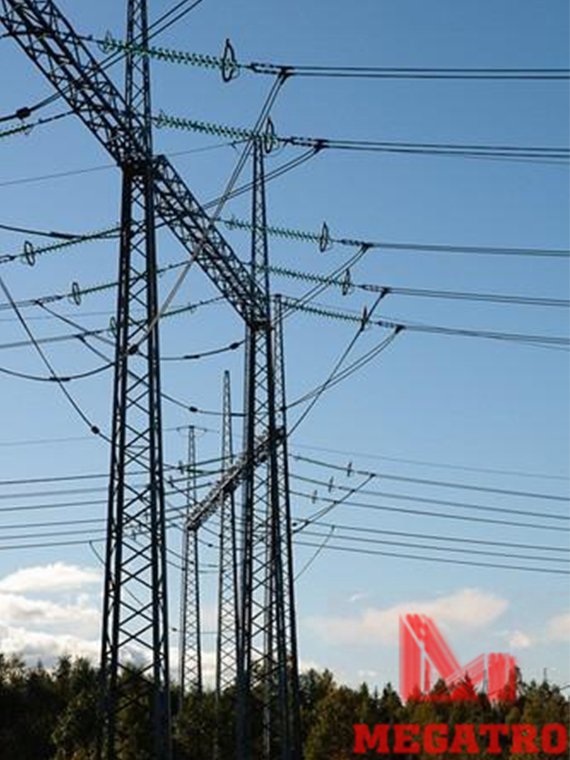

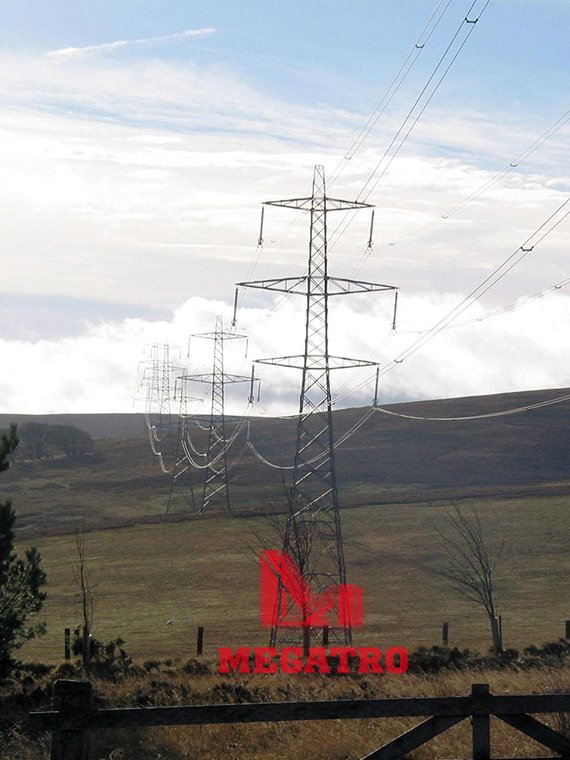

MEGATRO provide 138KV transposition lattice tower structure mainly for our overseas client. Since 2004, MEGATRO focus mainly international market and had export many kind of transmission structures to overseas clients. MEGATRO has been manufacturing lattice transmission tower & tapered steel poles for lighting, traffic control, communication and utility applications. MEGATRO pioneered the development of transmission tower, telecom tower, substation, and other steel structure and was also at the forefront in the design of Transmission tower.

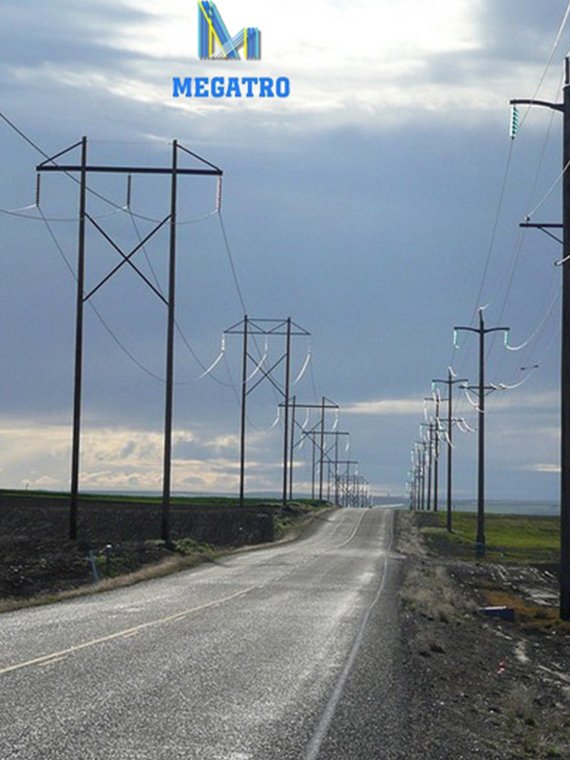

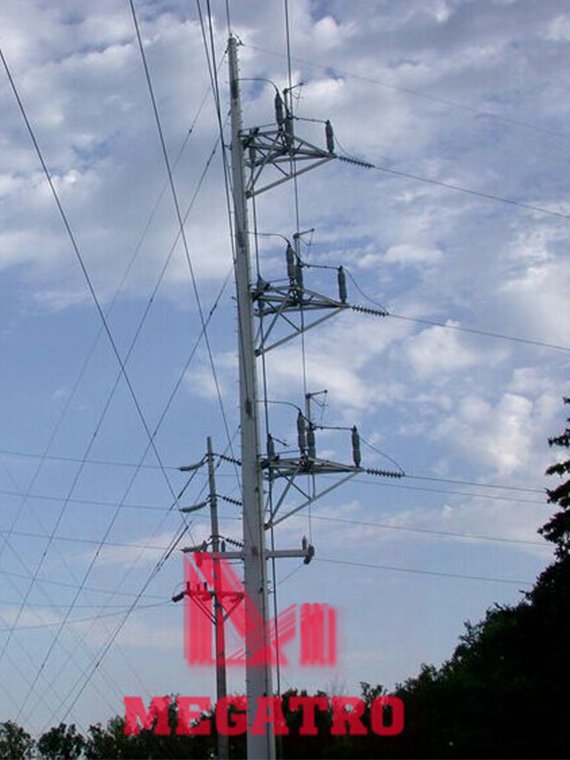

Today, with over 10 years of experience and our commitment to excellence, MEGATRO remains an industry leader in the manufacture and design of steel tubular & angular & monopole structures for all Highway, Municipal, Custom, telecom, lighting and electric Utility applications. MEGATRO has a complete staff of professional engineering personnel trained in the PLS Pole program and three different manufacturing processes for producing steel towers, poles and other supports. We utilize the latest versions of PLS-CADD, PLS-POLE, TOWER, AutoCAD and other CAD software.

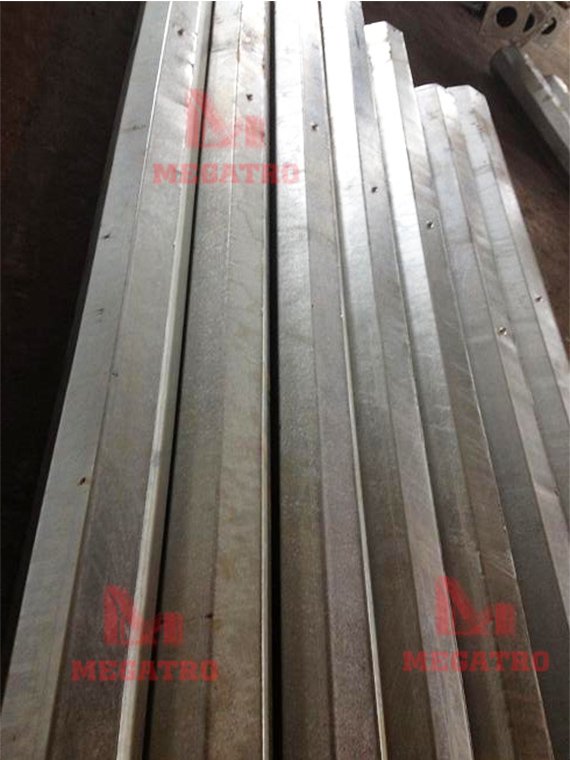

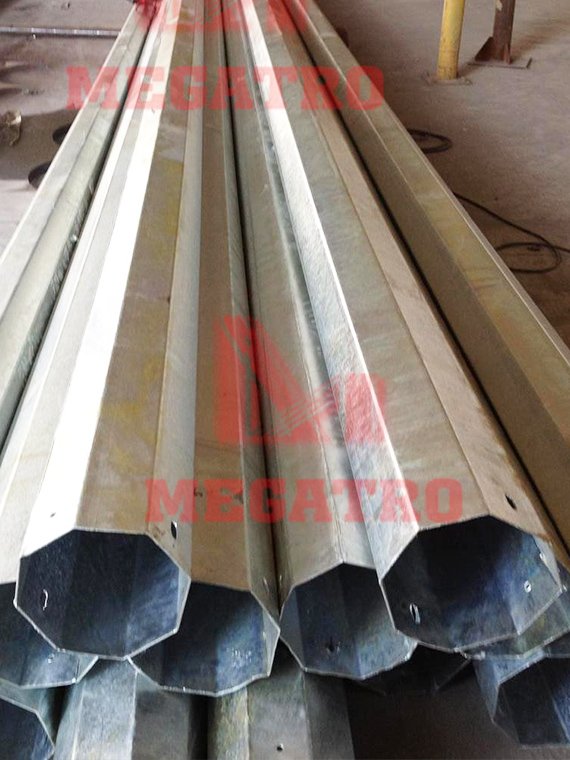

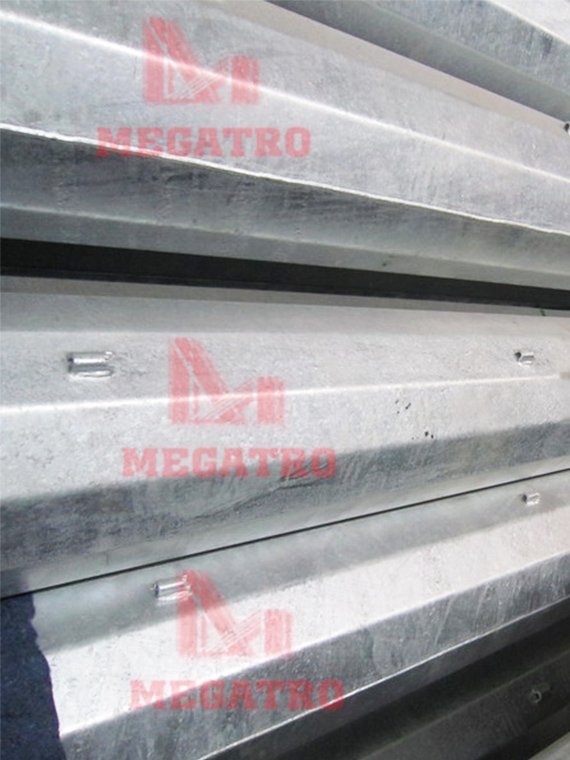

MEGATRO is one of the few manufactures who assemble a face of 138KV transposition lattice tower structure. This attention to quality may not be the cheapest process but it does insure every tower meets our high standards of quality. And it helps to reduce on-site construction cost due to mismatched assemblies. After fabrication all 138KV transposition lattice tower structure are delivered to the galvanizing facility to be Hot DIP Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. These strict procedures insure years of maintenance free towers. MEGATRO' 138KV transposition lattice tower structure systems can accommodate a variety of cross-arm. MEGATRO also offers a wide variety of accessories and mounts.

Other information:

Availability size: Based on the customer's requirements.

Material: Chinese material or as per clients requirement

Package: Both parties discuss before delivery

Port of Loading: Qingdao Port

Lead Time: One month or based on the customer's needs

Minimum order: 1 set

Fabrication standard: Chinese Standard or other standard which client accepted

Steel grades

Tower legs: Chinese steel Q345B, which same to ASTM A572 GR50

Other webs, bracing and not stress plate and angle steel: Chinese Q2138B, which same to ASTM A36

Plates: Chinese steel Q345B, which same to ASTM A572 GR50

Bolts: Chinese grade 6.8 and 8.8, which similar to ASTM A394

A) Dimension and tolerance for angle are according to GB/T1591-1994, similar to EN 10056-1/2

B) Hot dip galvanization in accordance with GB/T 13912-2002, which similar to ASTM A 123

C) The welding will be performance in accordance with AWS D1.1 or CWB standard

If any special requirement, we can design and discuss with client.