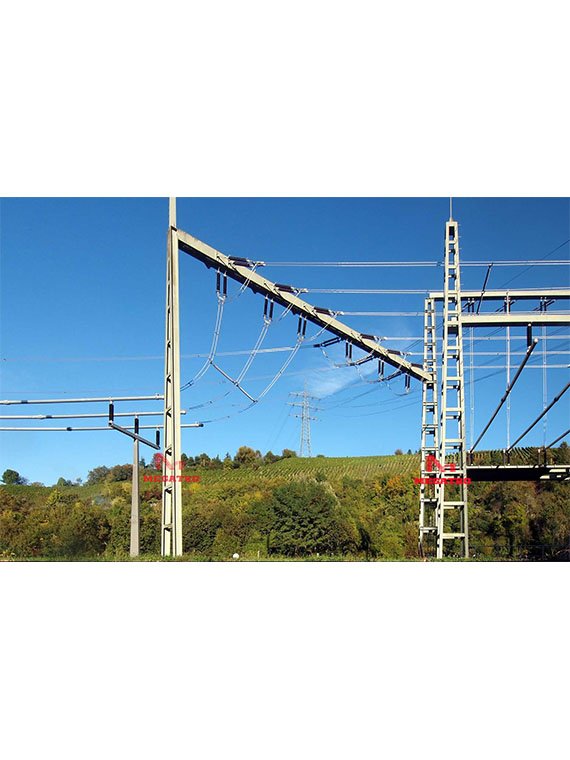

138KV SUBSTATION FRAMEWORK

Substation framework is a high-voltage electric system facility. It is used to switch generators, equipment, and circuits or lines in and out of a system. Substation includes Gantries and Equipment Support Structures. Gantry structures are mainly used for guiding the power conductor from last tower near substation to the electrical equipments in a substation. This structure consists of a number of columns and Girder beams, which depend on number of circuits of the line. Gantries are also used for line crossing. Power conductors of one line can be underpassed with the help of required number of gantries. Equipment Support Structures are columns, supporting electric equipments in a substation.

Depending upon the site and client's requirement, the Gantry and Equipment support structures can be mounted on substation building also.

MEGATRO mainly provide every type of 138KV substation gantries structure for our clients, especially for American regions, we manufacture them with complicated technology and adopted sophisticated production line.

Fabrication: Conform to clients drawings and technical requirements

Place of Origin: Qingdao, Shandong, China.

Availability size: Based on the customer's requirements.

Material: Chinese material or as per clients requirements

Package: Both party discuss and agreed before delivery

Terms of Payment: L/C; T/T

Minimum Order Quantity: 3 tons

Port of Loading: Qingdao Port

Lead Time: One month or based on the customer's needs.

Performance Standard

Besides conform to the drawing and design, the materials and fabrication of tower components shall conform to the following standards (Chinese Standard or other standard):

1. GB/T2694-2003 Transmission line tower - - Technical requirements for manufacturing

2. JGJ81-2002: Technical specification for welding for steel structure of building

3. GB9787-88: Measuring and allowable tolerance for hot-rolled equal angle

4. GB709-88: Measuring and allowable tolerance for hot-rolled plate and strip

5. GB/T699-1999: Quality Carbon Structural Steel

6. GB/T1591-1994: Low alloy high strength structural Steel

7. GB700-88: Carbon Structural Steel

8. GB222-84: Method of sampling steel for determination of chemical composition and permissible variations

9. GB/T228-2002: Method for Tensile testing of metals

10 GB/T232-1999: Method for Bending test of metals

11 GB/T5117-1995: Carbon Welding Rod

12 GB/T5118-1995: Low Alloy Welding Rod

13 GB/T8220-1995: Welding wires for gas shielding arc welding of carbon and low alloy steels

14 GB/T10045-2001: Carbon steel flux cored electrodes for arc welding

15 JB/T7949-1999: Weld outer dimensions for steel construction

16 GB50205-2001: Test Standard for Acceptance of Steel Structure

17 GB/T470-1997: Zinc Ingot

18 GB3098.1-2000: Mechanical properties of fasteners-Part 1: Bolts, screws and studs

19 GB3098.2-2000: Mechanical properties of fasteners-Part2: Nuts, and thread

20 GB3098.3-2000: Mechanical properties of fasteners-Part3: Fastening screw

21 GB/T5780-2000: Helical Bolts Grade C

22 GB/T41-2000: Helical Nuts Grade C

23 GB/T90-2002: Flat Washer Grade C

24 GB/T13912-2002: Metal Coating, Technical Requirement

We also adopt British, American and other international standard which client can accept.