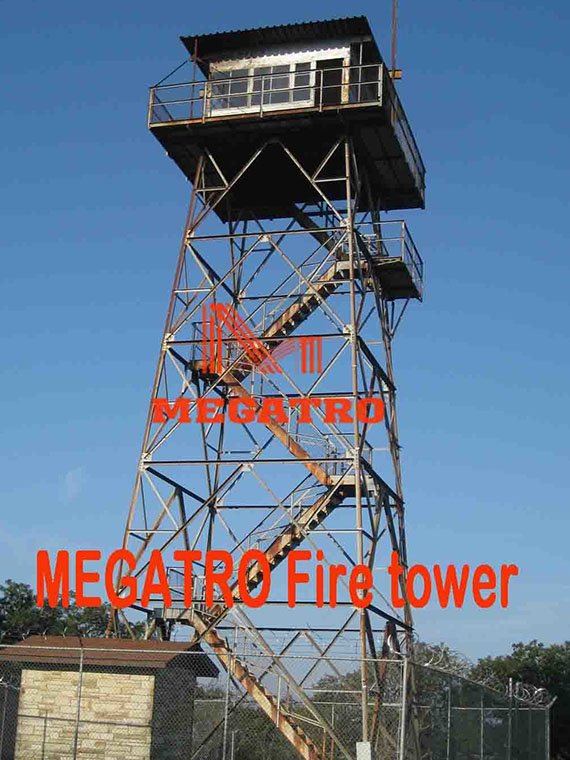

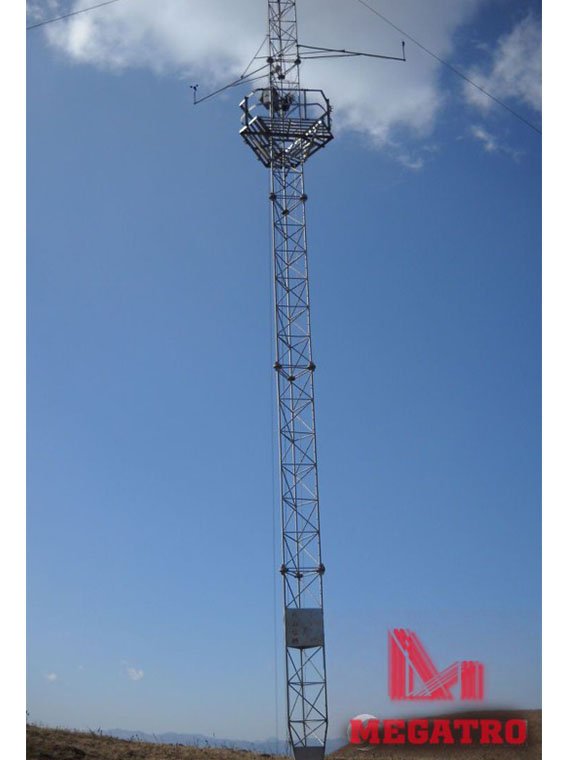

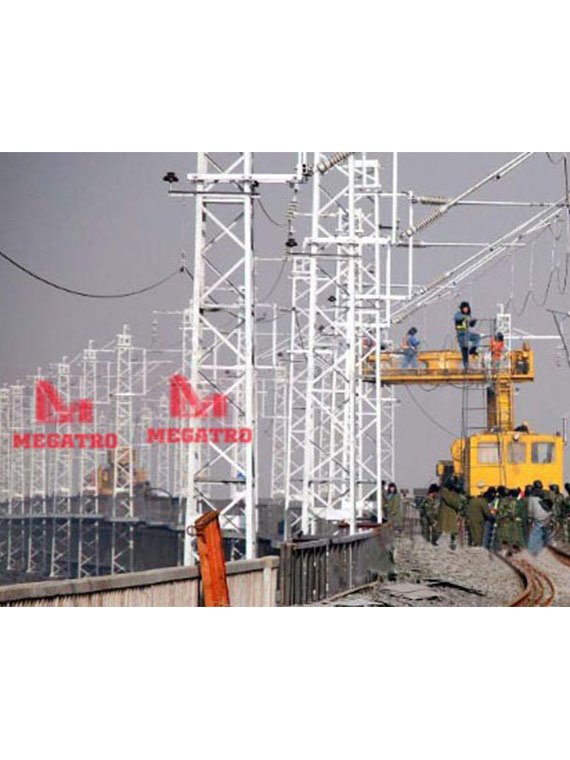

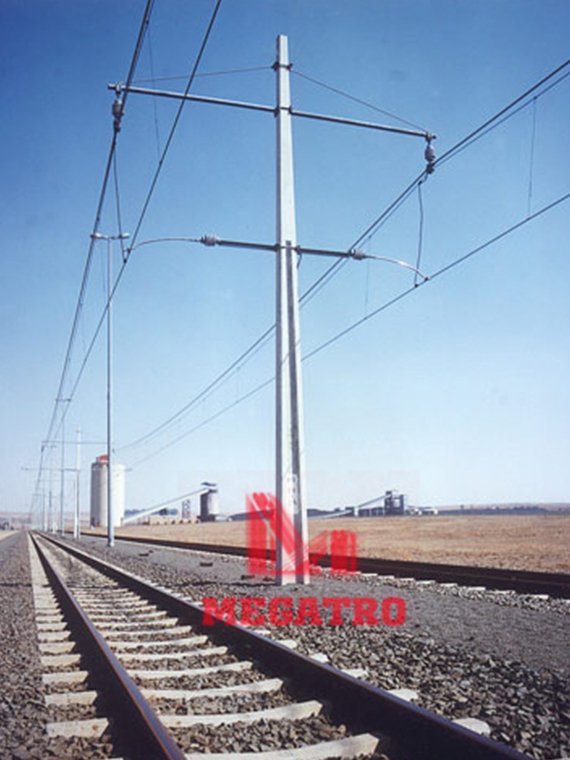

MEGATRO fabricates every type of angular steel torch towers, which designed by our skilled engineers with optimal plan, make the tower solid with lower weight, lower cost and high strength at site to meet client requirements.

After fabrication all towers are delivered to the galvanizing facility to be Hot Dip Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. These strict procedures insure years of maintenance free towers.

All torch towers must be produced according clients detailed drawings and other technical requirements, both party must reach an agreement for drawings before mast production.

Availability size: Based on the customer’s requirements.

Material: Chinese material or as per clients requirement

Package: both parties discuss before delivery

Terms of Payment: L/C, T/T

Minimum Order Quantity: 1ton

Port of Loading: Qingdao Port

Lead Time: one month or based on the customer’s needs

Performance Standard

Besides conform to the drawing and design, the materials and fabrication of tower components shall conform to Chinese Standard or other foreign standard which client can accept.